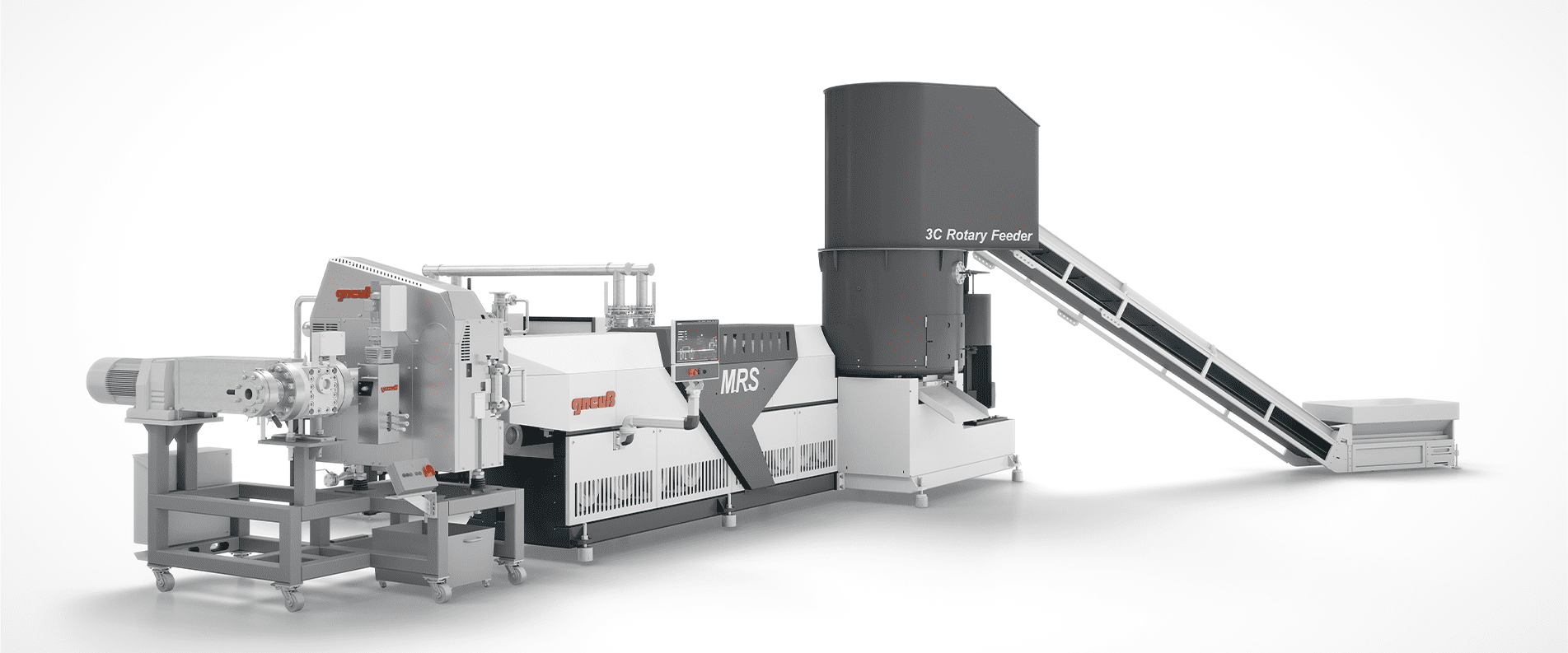

OMNI Recycling System

Gneuss’ MRS Extrusion Technology has proven itself as an alternative for the reprocessing of contaminated materials like polyester, nylon, polystyrene, polypropylene or other polymers. In combination with the highly efficient Gneuss Rotary Filtration Systems and optimized vacuum technology, customizable recycling lines tailor-made for a specific material can be engineered. Several Letters of Non Objection (LNOs) from America, Europe and local approvals in Latin America confirm the decontamination efficiency of the technology.

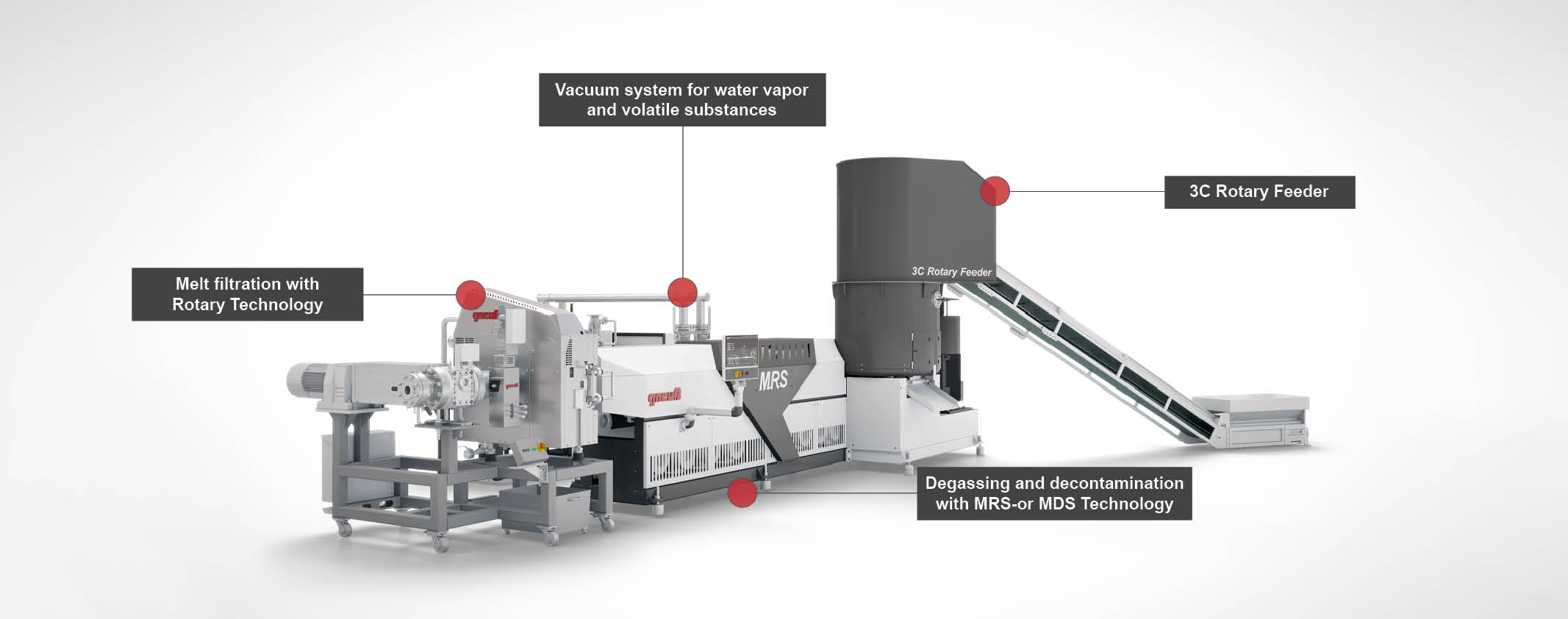

3C Rotary Feeder

The newly developed 3C Rotary Feeder makes it possible to use low bulk density materials without any external processing steps. A conveyor belt feeds shredded reclaim material into the hopper, where a fast-rotating disc with knives cuts, compacts and pre-conditions the material. The knives add energy into the material and start the heating and degassing process before the material is automatically fed into the extrusion system.

Extrusion system

In most cases, the patented multiple screw Gneuß MRS extruders is applied. Thanks to the sturdy satellite screws, the degassing and homogenising performance of the extruder is second to none. The vast polymer surface area under vacuum in the MRS section of the extruder ensures highly efficient decontamination, homogenisation and control of the viscosity (in particular when reprocessing PET).

Alternatively, the new (and likewise patented) MDS extruder can be applied for certain applications. This extruder is characterised by a new kind of combination of heat input and devolatilization. Thanks to the changes in the extruder screw diameter, a unique new combination of heat input and devolatilisation as a result of the changes in the extruder screw diameters along its length.

Specially developed for high viscosity polymers, the Gneuß MRSpure multiple screw extruder is operated in tandem with an upstream extruder for plasticising the polymer. Depending on the requirements, a single screw or twin-screw extruder is used for plasticising the polymer prior to decontamination/devolatilization on the special MRSpure extruder. This extrusion system is typically used for example for reprocessing not only HDPE bottle caps and HDPE milk bottles, but also LDPE post-consumer material.

| MRS extruder | throughput rate | ||

| PET | 250 – 2.200 kg/h | ||

| PP + PE | 180 – 1.400 kg/h | ||

| PA | 250 – 2.000 kg/h | ||

| PS | 200 – 1.600 kg/h |

RSFgenius Filtration System

Gneuss’ top model, the RSFgenius, operates with an integrated back-flushing system offering self-cleaning for very demanding applications and highest quality requirements. Screens can be automatically re-used up to 400 times, and filtration finenesses below 10 microns/1200 mesh are available.

Vacuum technology

In order to be able to extract volatile impurities, Gneuss has developed specialized vacuum systems, some of which have patented separation systems. Due to the large melt surface in the extruder, the suction capacity is much higher than with conventional systems, so that large quantities of volatile impurities can be extracted from the polymer melt and separated from the vacuum stream by separation systems. In addition to a water ring pump vacuum system, Gneuss also offers deep vacuum systems with corresponding separation devices.

VIS

The Online Viscometer was developed with the goal of achieving measurements which are comparable with laboratory results and to provide a system which provides these accurate values permanently and without influencing the process. Using a high-precision, high-conveying gear pump, a small partial flow of the polymer melt is diverted from the main melt channel and then forced through a precisely manufactured slotted capillary. The viscosity measured there is directly related to the molecular chain length, on which in turn the mechanical properties such as tensile strength and stiffness depend. Quality assurance can be improved by recording and storing this data through the viscometer.

Advantages of the OMNI:

- all kinds of input material can be processed, including waste with low bulk densit such as fibre or biaxially oriented film

- highly flexible: all kinds of materials can be processed, such as PS, PP, PE, PET, PLA, PA

- super clean recycling technology: food contact compliance – even for post-consumer input materials, odour reduction

- minimised residence time, gentle processing and highest quality products

- closed recycling loop – no downcycling

- energy efficient, compact lines

Technical options:

- direct adaptation to sheet, strapping tape or fibre

production lines (no need for the intermediate step of

pelletising) - blending of additives (in pellet or liquid form)

- highly efficient, process-constant fine filtration

- individually configured feeding systems, including the

Gneuss 3C Rotary Feeder

Do you need more detailed information? Request our technical reports and brochures now!

Request