Gneuss’ PET recycling system: The OMNIboost Series

Gneuss’ OMNIboost series is a PET recycling system specifically designed for recycling polyester waste for applications with high viscosity requirements. This PET recycling machine builds upon the well-known OMNI series with an MDS extruder and complements it with a Gneuss JUMP reactor, which, in combination with a specially designed vacuum system, allows a significant increase in viscosity.

Applications for this PET recycling machine include PET bottle-to-bottle recycling and recycling of polyester waste with widely varying input viscosities, such as in the recycling of fiber waste.

Design of the OMNIboost PET recycling system

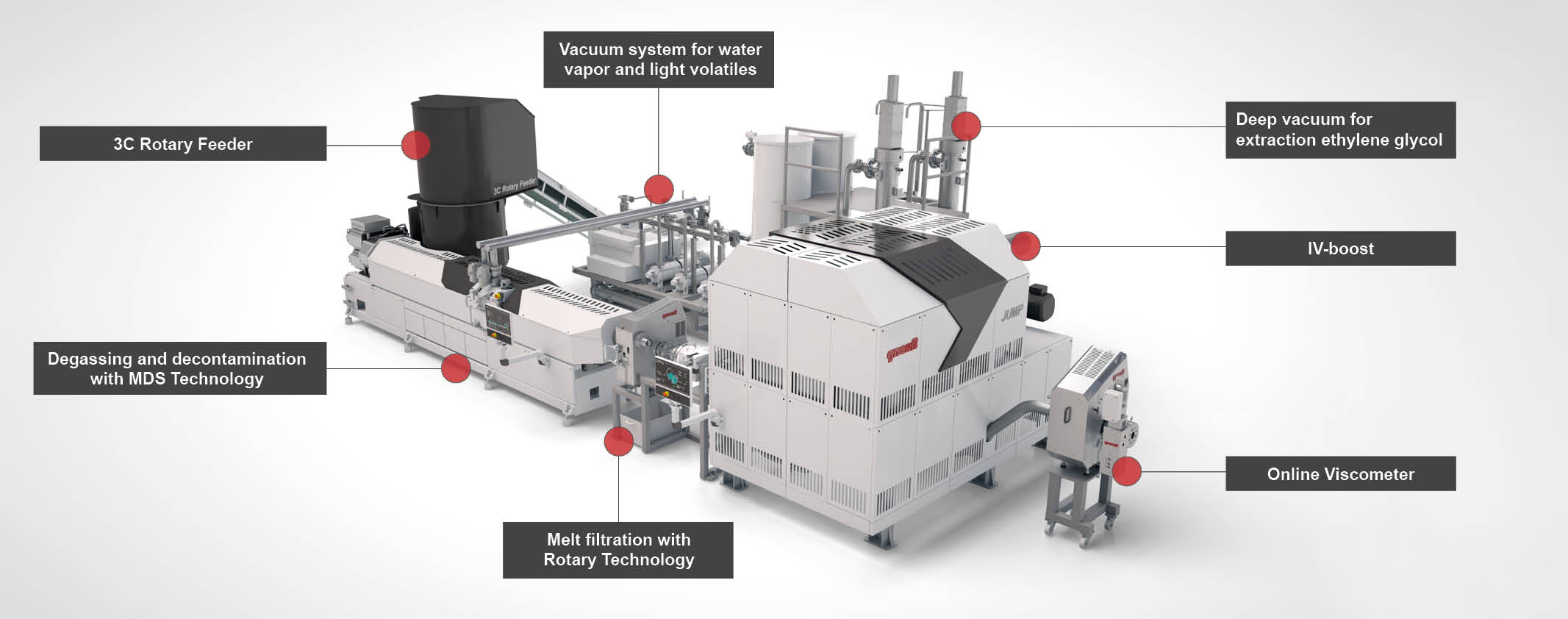

3C Rotary Feeder

The newly developed 3C Rotary Feeder enables processing of low bulk density materials without external processing steps. A conveyor belt feeds shredded reclaim into the hopper where a high-speed rotating disc with knives cuts, compacts and pre-treats the material. The knives feed energy to the material and start the heating and degassing process before the material is automatically fed into the extrusion system.

Extrusion system

The OMNIboost recycling machine uses the new and patented MDS extruder, which is characterized by alternating screw diameters and a novel interaction of heat input and degassing.

The basic concept of the MDS is to briefly thermally charge the melt before it enters the degassing zone, thus achieving an enhanced degassing effect. This is realized by widening the screw diameter at the end of the metering zone, followed by a long deep-cut degassing zone with a likewise widened screw diameter.

The result is a highly efficient degassing performance with gentle melt handling. The system’s robust and flexible single-screw design makes it ideal for high-quality recycling of most polymers.

| MDS extruder | throughput rate | ||

| PET | 35 – 2.000 kg/h |

RSFgenius rotary filter

Gneuss’ top model, the RSFgenius rotary filter, is also used in the OMNIboost. This model operates with an integrated backflush system for self-cleaning for very demanding applications and highest quality requirements. The screens can be automatically reused up to 400 times and filter finenesses below 10 µm are possible.

JUMP reactor

The OMNIboost PET recycling system features a JUMP polyreactor that can raise the IV value of a PET melt up to 0.95 dl/g. In the JUMP, the polymer passes over several slowly rotating elements that create a polymer film whose surface is constantly renewed. The reactor vessel is under vacuum, reliably removing volatiles. By controlling the residence time in the reactor, the vacuum, the filling level and the rotation speed of the agitators, the polycondensation reaction can be influenced to achieve the desired product properties. The JUMP is a robust and reliable liquid phase polycondensation (LSP) system and a compact, fast and efficient alternative to conventional solid state systems (SSP). It allows the polymer to be reintroduced directly into the production process without the need to remelt the PET.

Vacuum technology

In order to be able to extract volatile impurities, Gneuss has developed specialized vacuum systems, some of which have patented separation systems. Due to the large melt surface in the extruder, the suction capacity is much higher than with conventional systems, so that large quantities of volatile impurities can be extracted from the polymer melt and separated from the vacuum stream by separation systems. In addition to a water ring pump vacuum system, Gneuss also offers deep vacuum systems with corresponding separation devices.

Online Viscometer VIS

If required, the OMNIboost PET recycling machine includes an online viscosity measurement system that enables precise measurement of the melt viscosity. Using a high-precision, high-conveying gear pump, a small partial flow of the polymer melt is diverted from the main melt channel and then forced through a precisely manufactured slotted capillary. The viscosity measured there is directly related to the molecular chain length, on which in turn the mechanical properties such as tensile strength and stiffness depend. Quality assurance can be improved by recording and storing this data through the viscometer.

Advantages of the OMNIboost PET Recycling System

The PET recycling system OMNIboost opens up a wide range of advantages including both environmental and economic aspects.

- processing of very light materials possible such as BOPET film waste or PET fiber waste

- gentle preheating of the material, maintaining the achieved extrusion temperature until the finished end product is manufactured

- shortest residence times due to polycondensation in the melt

- highest flexibility in the strength of the end product thanks to dwell time control

- extremely compact design

- energy-efficient

- safe plant technology of excellent quality

Technical options of the PET Recycling System OMNIboost

The PET Recycling System OMNIboost offers the following technical options:

- addition of additives (solid/liquid)

- fine and ultra-fine filtration

- customized and/or direct feeding into the 3C Rotary Feeder

Do you need more detailed information? Request our technical reports and brochures now!

Request