- Typical materials: PET, PA 6, PA 66, PP

- Common throughputs up to 4.000 kg/h

- Filtration finenesses down to 6 µm

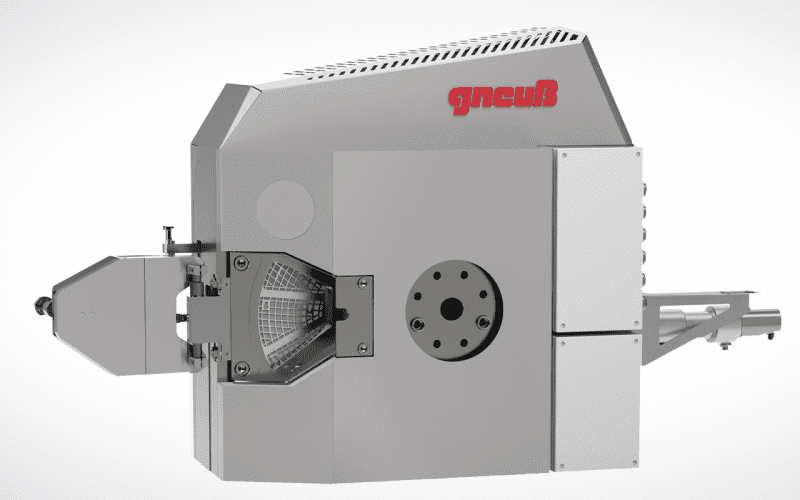

In the manufacturing of textile fiber/filament a high process consistency regarding pressure and temperature is an essential prerequisite for an efficient production. Minimization of the melt dwell time in the filtration system is very important. High throughput rates make a fully-automatic mode of operation of the filtration system without any influence on the process necessary. The RSFgenius was developed especially for these requirements and makes continuous cost reductions in the manufactu – ring process with top qualities possible. The filtration system is suitable for extrusion spinning as well as for continuous direct spinning lines.