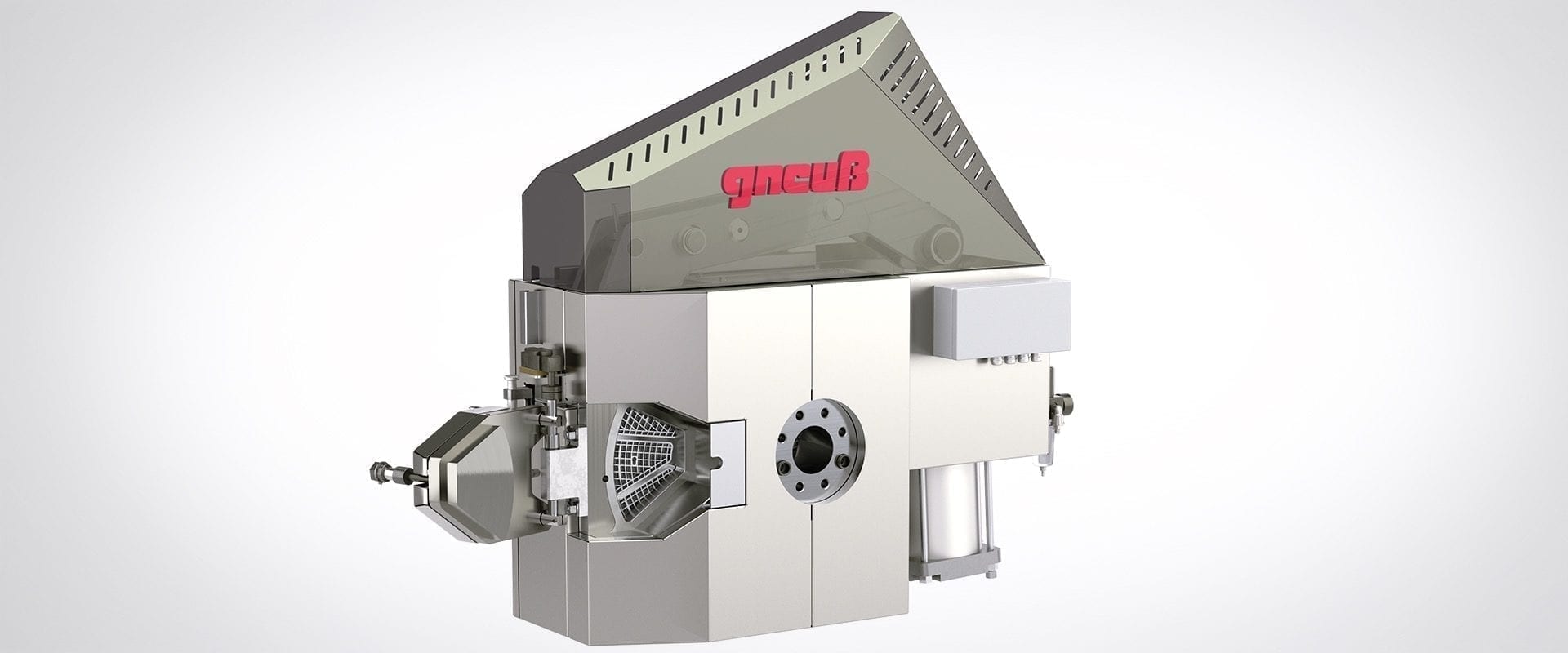

Process constant et pression constante

La SFXmagnus fonctionne de manière entièrement automatique et avec constante de process et de pression. Elle peut être utilisée pour quasiment toutes les applications et se distingue par sa surface de filtre active particulièrement grande, par sa construction compacte et par sa grande facilité d’utilisation. Les changements de filtre n’ont aucune influence sur la qualité du produit.

The advantages of the SFXmagnus Filtration System

- Economic

The extra large active screen surface area in relation to the screen changer size allows a unique economic efficiency of the SFXmagnus. The return on investment is realized within a very short period of time. - Constant

By assuring a consistent active screen area, the pressure can be kept nearly constant during the whole production process. Melt temperature, viscosity and throughput are also free of variations at any time. Constant quality of the final product is guaranteed even during screen changes. - Quality

Thanks to the optimized melt channel flow path and completely airtight encapsulated design, the requirements with regard to the purity and quality of the melt can be achieved and permamently maintained. - Streamlined

The optimized rheological design of the melt channel flowpath ensures a minimized residence time (< 1 minute) thus ensuring for example fast material or color changes. - Straightforward

The control system informs the operator in advance of an upcoming screen change. The screens can be changed quickly and easily and without any influence on the process or pressure consistency. - Compact

The remarkably compact size of the SFXmagnus allows an easy and inexpensive integration even within limited space. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low.

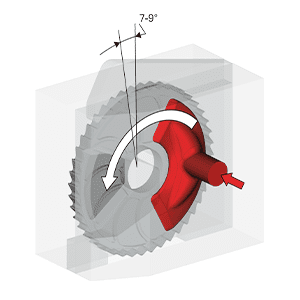

Fonctionnement

Lorsque la pression augumente avant le filtre, le disque tourne automatiquement grâce au vérin pneumatique ou hydraulique. Ainsi, la surface de filtration disponible reste toujours constante et la pression augmente très peu avant le système de filtre durant tout le processus de production.

Lorsque la pression augumente avant le filtre, le disque tourne automatiquement grâce au vérin pneumatique ou hydraulique. Ainsi, la surface de filtration disponible reste toujours constante et la pression augmente très peu avant le système de filtre durant tout le processus de production.

Le retrait des filtres est effectué sans que cela ne perturbe le processus de production.