Extruder manufacturer: Efficient solutions for the plastics industry

As a well-known extruder manufacturer, Gneuss specializes in the design and development of high-quality equipment for the plastics industry. Our customized solutions enable companies to optimize their production processes and make them more efficient. With many years of experience and a team of experts, we offer innovative technologies and reliable products that meet our customers’ highest requirements.

Extrusion

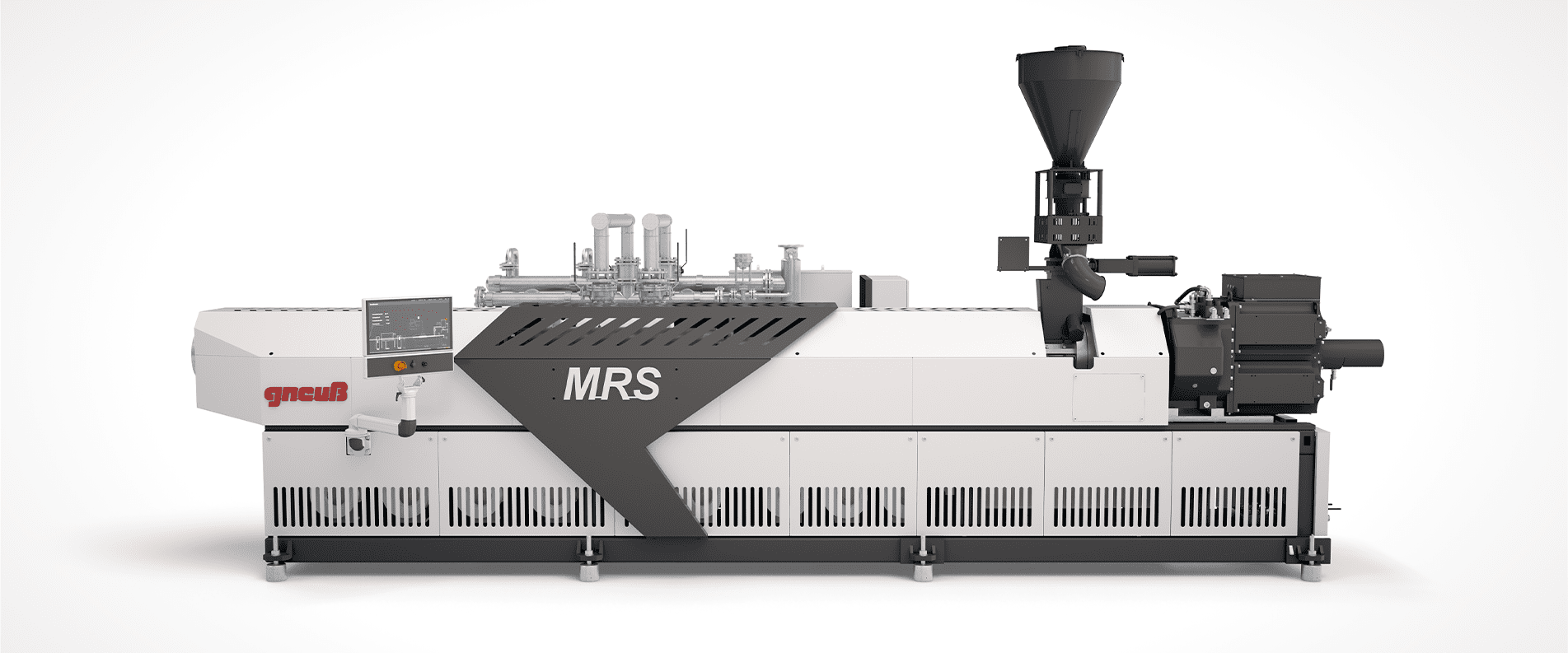

Extrusion Systems

The patented Extrusion Systems offers completely new possibilities with regard to the efficient degassing and extrusion of polymer melts.

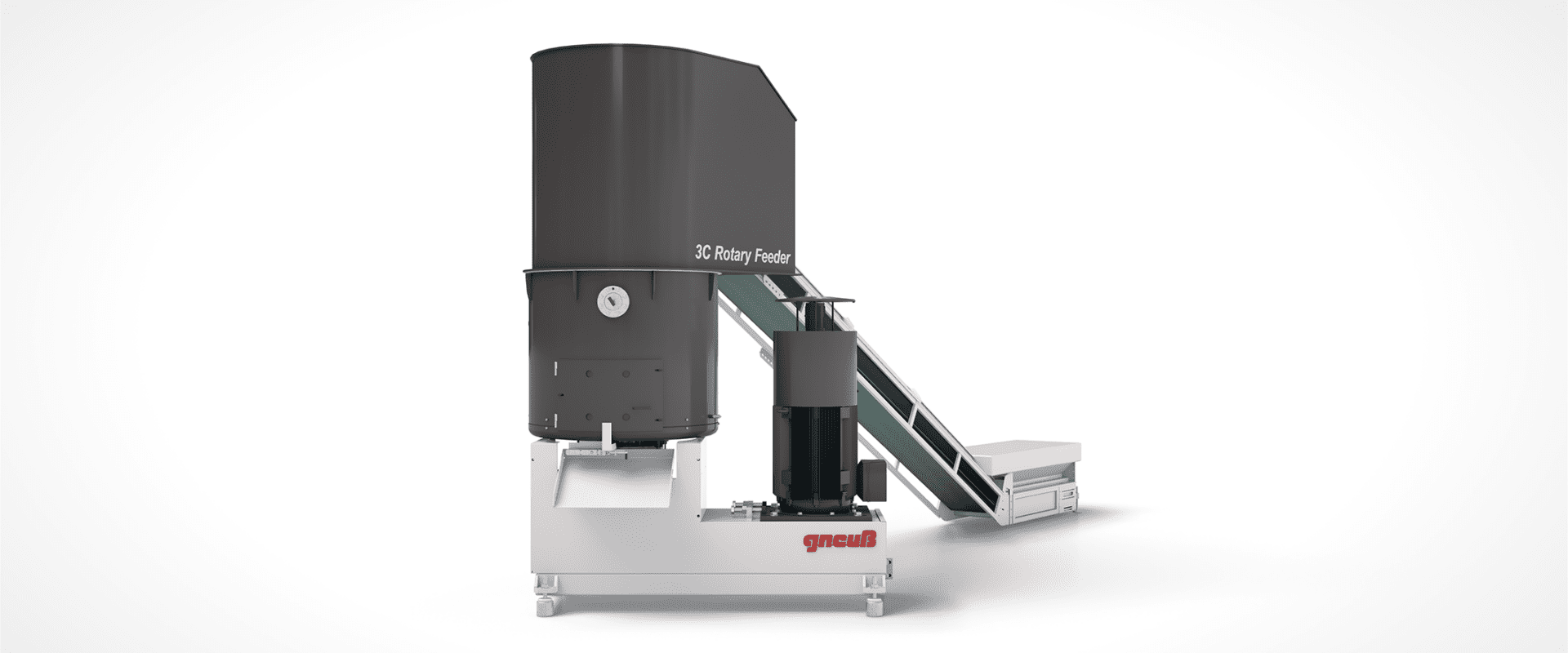

3C Rotary Feeder

The 3C Rotary Feeder enables the processing of materials with low bulk density without external, upstream processing steps.

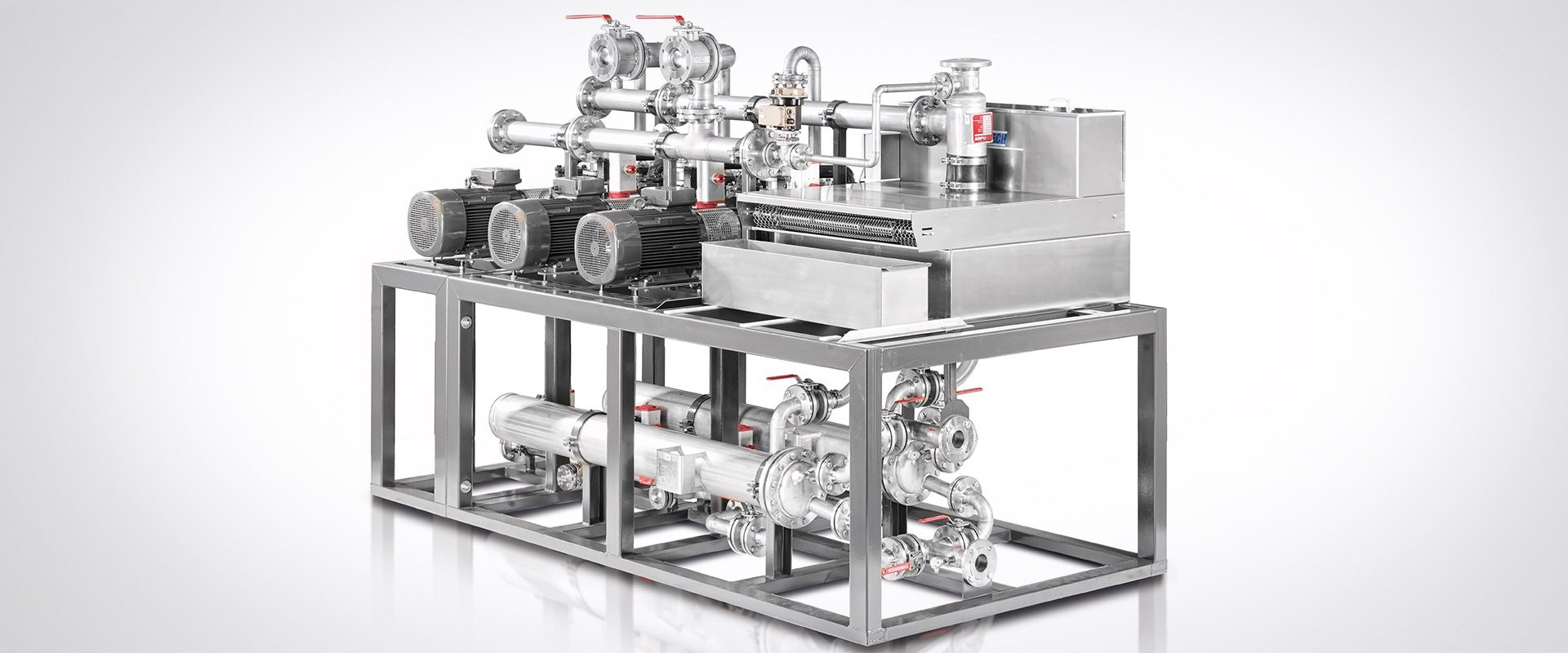

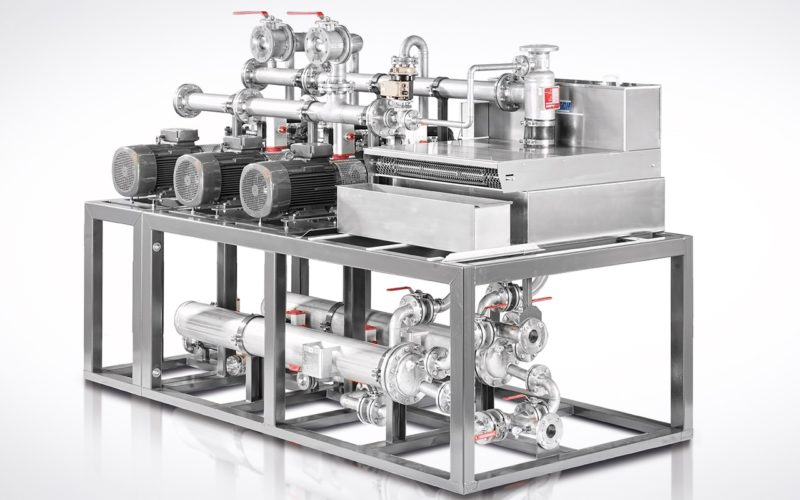

Vacuum Technology

The vacuum system plays a key role in the devolatilization process.

Control Technology

The control system is an important element in any extrusion line.

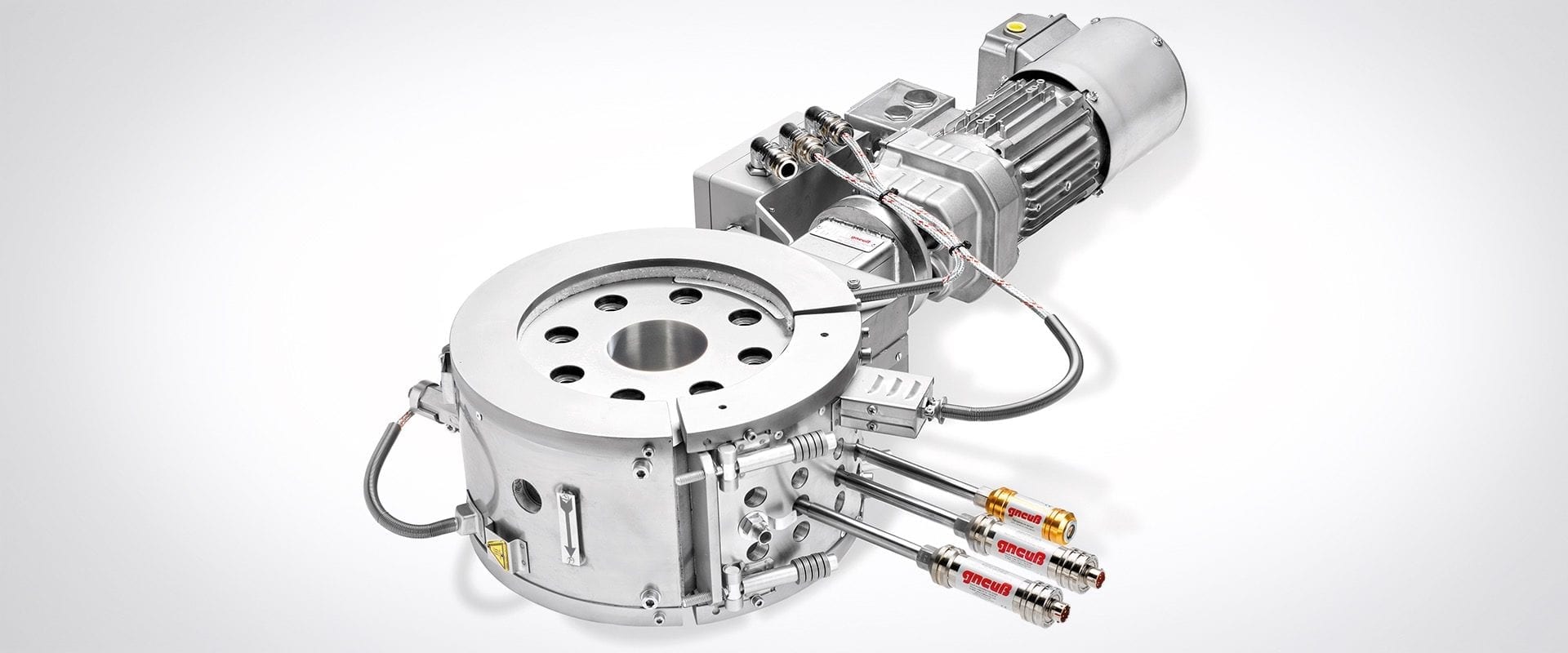

Online Viscometer VIS

The Online Viscometer not just monitors but in combination with upstream equipment can also control the melt viscosity in real time.

Gneuss extrusion systems – flexible for various applications

Gneuss extrusion lines are used in a wide range of applications. Whether you manufacture plastic sheet, film, fibers, profiles, pipes, hoses or other products – we can offer you an optimized solution. As an experienced extruder manufacturer we understand the diverse requirements of different industries. Therefore, Gneuss created high-performance extrusion lines for the production of high-quality products with extrusion lines that can be supplemented with various Gneuss products and technologies:

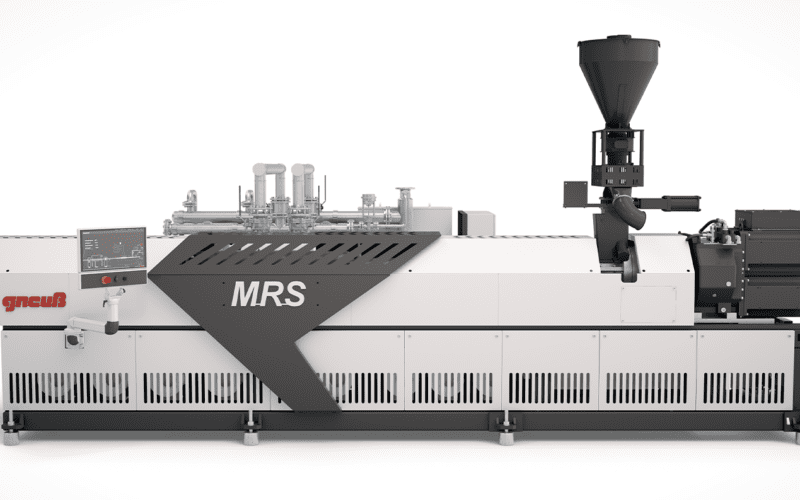

- Extrusion systems: The patented Extruders offer completely new possibilities with regard to the efficient devolatilization and decontamination of polymer melts. A key element here is the multi-rotation system (MRS) which is based on a single-screw extruder concept but equipped with a multiple screw section. A modification is the recycling extruder MRSpure.

- 3C Rotary Feeder: Combination of cutting, compacting and conditioning before the extrusion process starts.

- Vacuum Technology: The vacuum system for extracting volatile impurities plays a key role in the devolatilization process.

- Control Technology: The control system is an important element in any extrusion line.

- Online Viscometer VIS: The Online Viscometer not just monitors but in combination with upstream equipment can also control the melt viscosity in real time.

Elevate your manufacturing with the many benefits of our extruders

We attach great importance to the flexibility and adaptability of the equipment . Therefore, we offer optimal solutions that meet the individual needs and requirements of our customers. Gneuss extrusion lines can be integrated into existing extrusion lines or operated as stand-alone systems.

With extrusion lines, plastics processers can benefit from numerous advantages, including improved product quality, higher production speeds, optimized process efficiency and increased sustainability through the use of recycled materials. Gneuss’ innovative extruders help optimize production processes and strengthen our customers’ competitiveness.

Extruder manufacturer for high quality solutions

Gneuss extruders are reliable, efficient and durable. By using advanced control technology and automated processes we enable optimal utilization of resources and minimization of waste. As an extruder manufacturer, we recognize the importance of sustainable production and therefore focus on energy-efficient solutions that reduce our customers’ environmental footprint. With years of expertise and commitment to quality and customer satisfaction, we help processors worldwide to optimize their production processes and manufacture high-quality end products.

Do you need more detailed information? Request our technical reports now!

Request