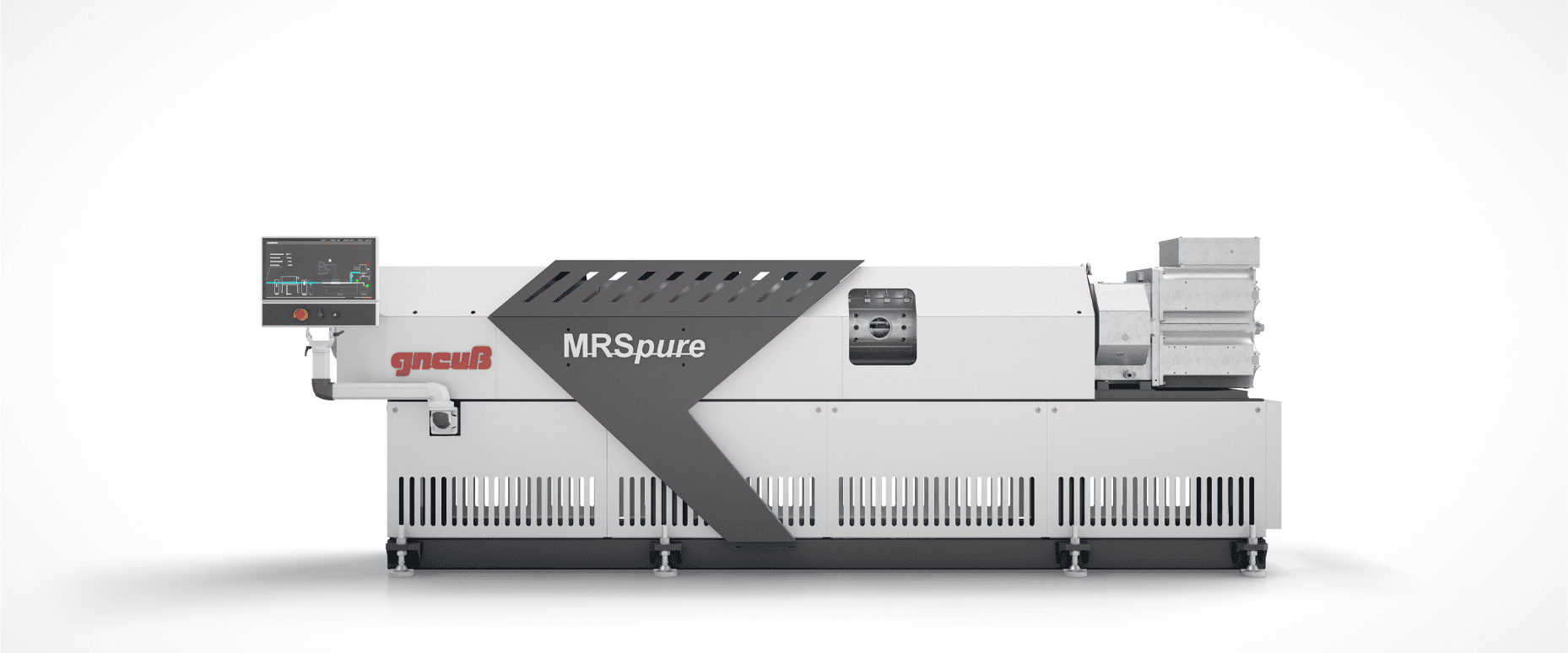

MRSpure recycling extruder by Gneuss

The MRSpure extruder is an extrusion system by Gneuss based on the technology of the MRS extruder (Multi-Rotation-System), but it separates the melting process from the degassing process. With the MRS technology, the polymer melt is delivered into a large single screw drum. The drum contains several small extruder barrels, parallel to the main screw axis. Installed in these small extruder barrels are the satellite screws, which are driven by a ring gear in the main barrel. The satellite screws rotate in the opposite direction to the main screw while they rotate around the screw axis. This increases the surface exchange of the melt disproportionately. This unique MRS technology enables extremly efficient and gentle decontamination of heavily contaminated materials without pre-drying and thus even offers compliance with global food contact standards.

Design of the MRSpure recycling extruder

In contrast to the standard MRS, the MRSpure recycling extruder has a melting extruder upstream of the MRS element. In this way the two process steps “melting” and “degassing/ deodorizing/ decontamination” are decoupled in terms of process technology, so that the process parameters can be optimized individually for each process step. Depending on the requirements placed on the melting process, a single or twin-screw extruder can be used. This makes it possible to retrofit the MRSpure into an existing line and use it for degassing and decontamination tasks. The MRSpure is used in particular for highly viscous and complex polymers and their mixtures. Typical applications include closed-loop recycling of HDPE bottle caps, HDPE milk bottles or LDPE waste and mixtures of different polymers. Various international food approvals confirm the high cleaning efficiency (super-clean), even for direct contact with food. This also allows this technology to be used for the recycling of packaging products in the cosmetics industry.

Areas of applications

The MRSpure recycling extruder is particularly used for highly viscous and complex polymers and their mixtures. Typical applications include closed-loop recycling of HDPE bottle caps, HDPE milk bottles or LDPE waste and blends of different polymers. Various international Letters of Non-Objection confirm the high cleaning efficiency (super-clean), even for direct contact with food. This allows for the material to be used for the packaging of products in the cosmetics industry

| MRSpure Extruder | throughput rate |

| PET | 35 – 2.000 kg/h |

| PP + PE | 25 – 1.600 kg/h |

| PA | 28 – 1.900 kg/h |

| PS | 30 – 1.500 kg/h |

Advantages of the MRSpure recycling extruder

- Decoupling of plasticizing and degassing/ decontamination/ deodorizing

- Free choice of melting technology

- Use as a downstream degassing system after an existing extruder (retrofit)

- Individual optimization of the separate process steps enables maximum flexibility

- Optimum degassing/deodorizing/decontamination

- Broad process spectrum

- Wide range of materials

An overview of application examples

The MRSpure recycling extruder offers a wide range of applications for the efficient recycling of various types of plastic waste, including:

- HDPE bottle caps

- HDPE milk bottles

- HDPE shampoo or shower gel bottles

- LDPE waste

- Processing of PS, PP, PE, PET, PLA, PA and many more

News

Closed-loop recycling of HDPE – Pellets for food contact with OMNImax recycling system

High-density polyethylene (HDPE) is widely used for a variety of products due to its durability and strength, with a recycling stream facilitated by bottle deposit legislation. The Gneuss OMNImax recycling system using the MRSpure extruder efficiently purifies HDPE, allowing it to be reprocessed into high-quality products, including food contact materials. This system is highly flexible and cost-effective, with features such as low energy consumption and high cleaning efficiency.

Benötigen Sie noch weitere Informationen? Bestellen Sie unsere technischen Fachberichte jetzt!

Kontakt