Gneuss’ plastic recycling line: The OMNI series

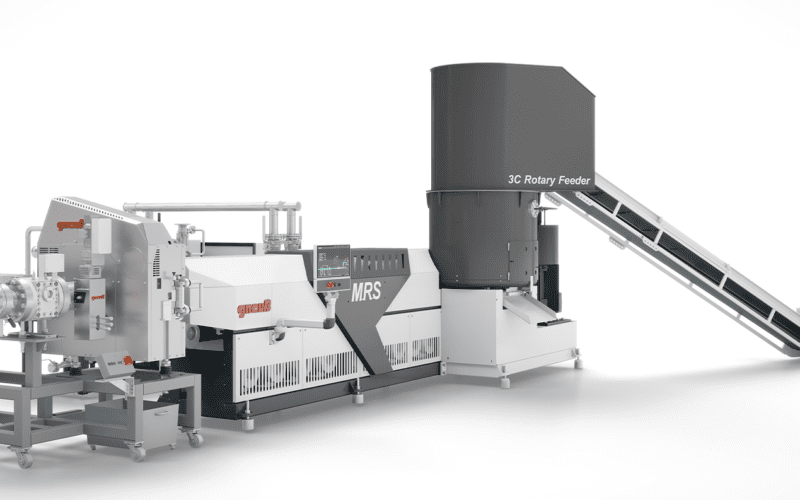

Gneuss’ “OMNI” plastic recycling lines offer innovative, technological solutions to recycle plastics in an efficient and environmentally friendly way. They are characterized by their outstanding processing capacity and enable the recycling of different types of plastic waste. With the help of Gneuss key components such as the 3C Rotary Feeder, the MRS and MDS extrusion systems, Rotary Filtration Systems, Vacuum Systems and the Online Viscometer, increasing recycling demands such as direct food contact, odor removal and purity can be met.

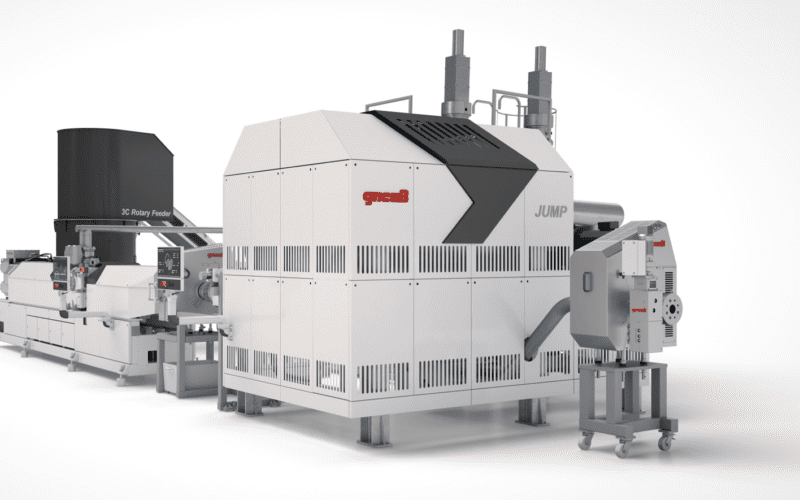

The OMNI plastic recycling line

In order to meet the specific needs of a wide range of recyclables, polymers and application requirements, the OMNI plastic recycling line offers three different models. The exceptional performance of these three OMNI plastic recycling models makes it possible to close (closed) recycling loops, which was previously not possible.

OMNI Plastic Recycling Line

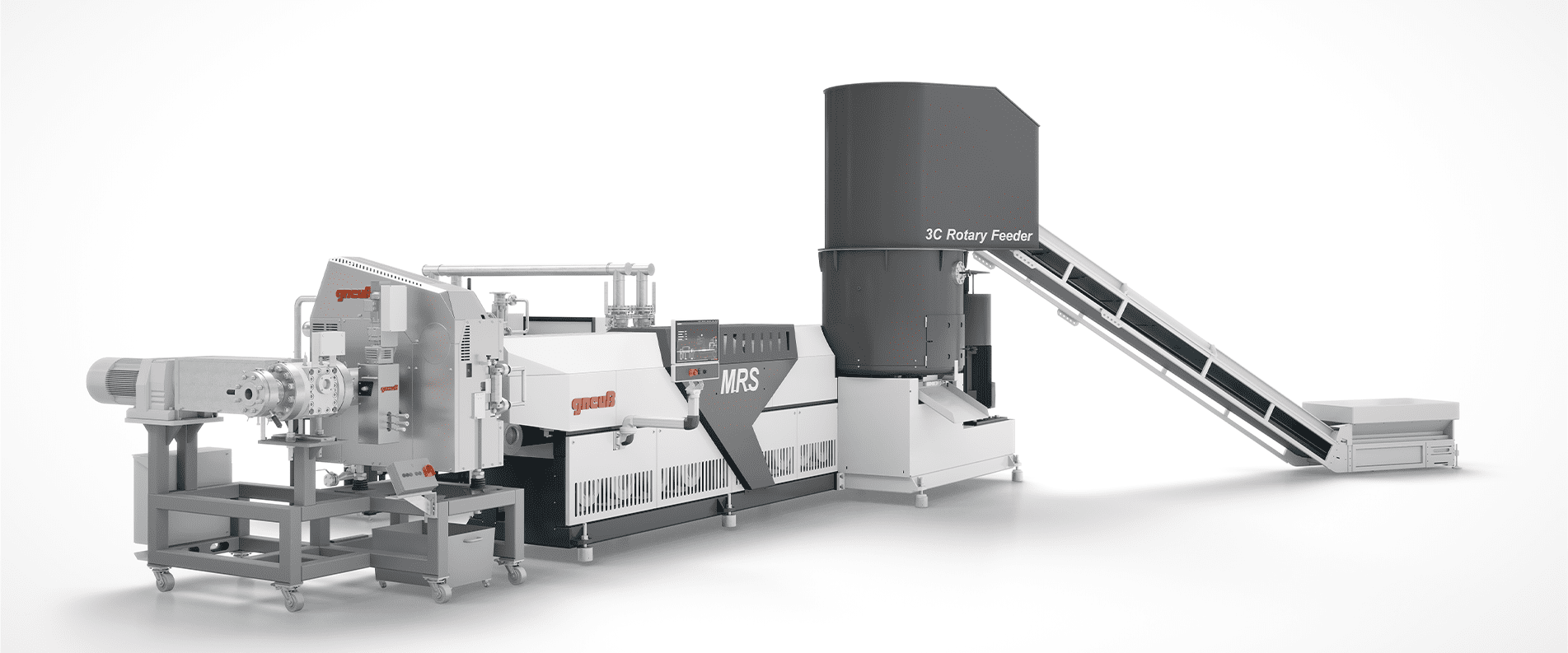

OMNI

The OMNI plastic recycling line processes industrial and post-consumer waste from polymers of all types.

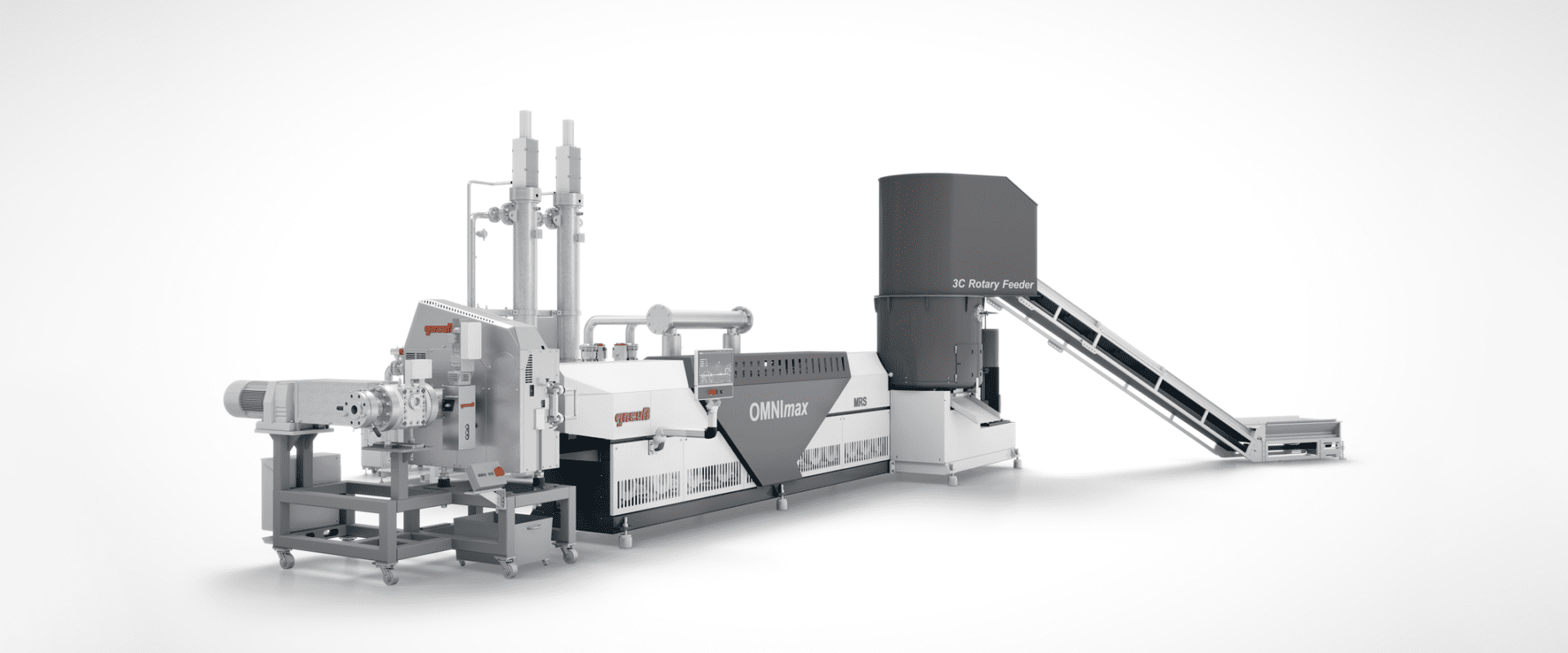

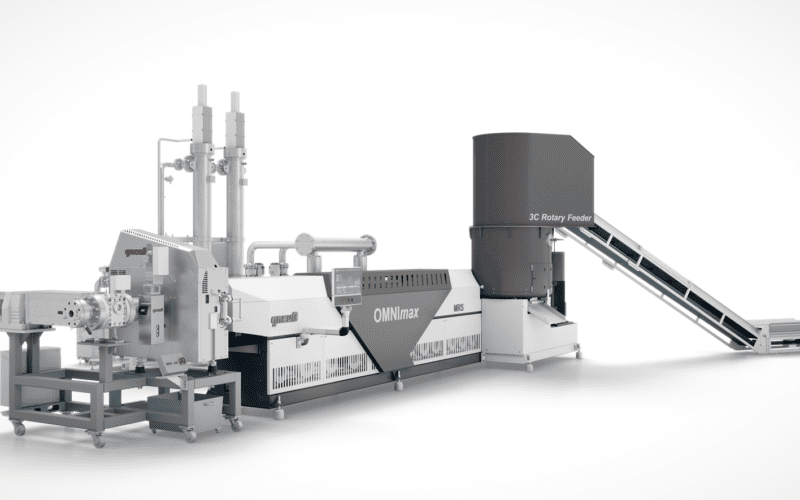

OMNImax

The OMNImax plastic recycling line cleans powerful industrial and post-consumer waste.

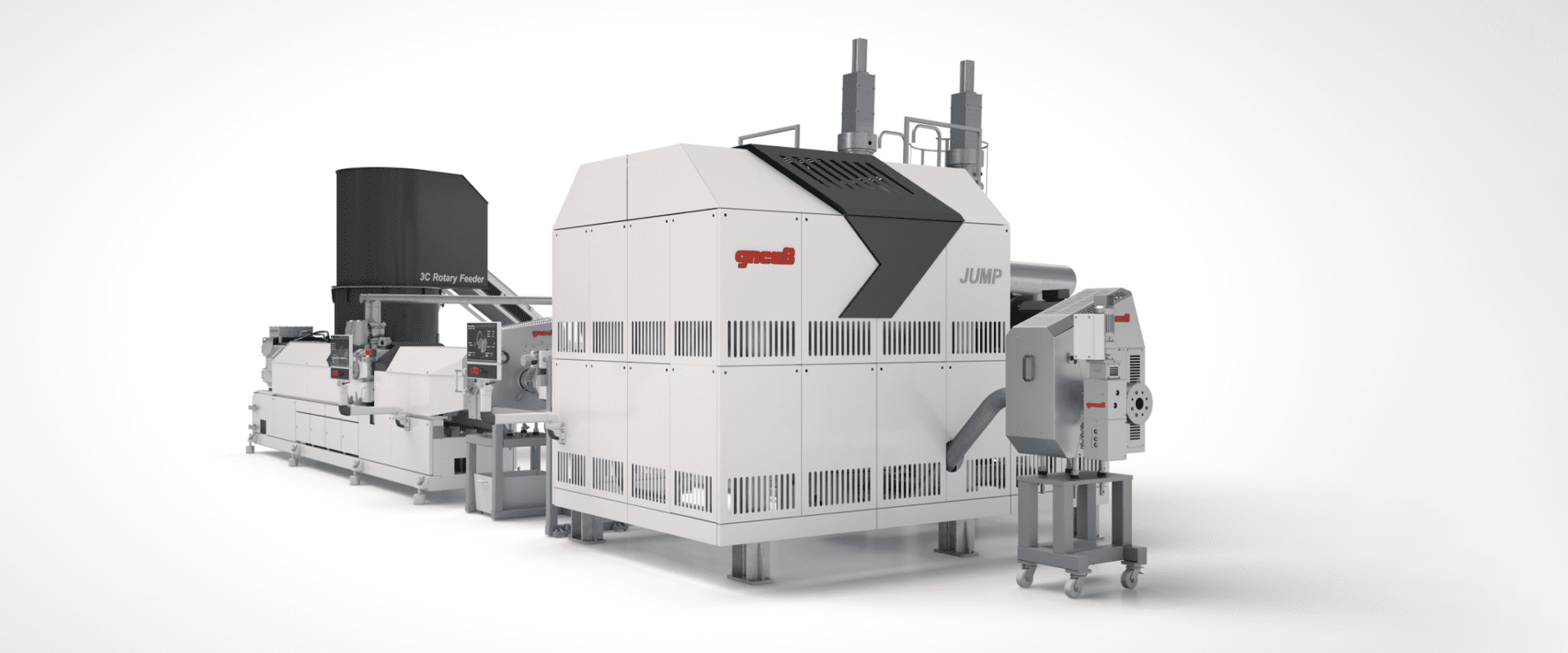

OMNIboost

The OMNIboost plastic recycling line is a PET recycling system, which processes industrial and post-consumer PET waste directly into high-quality high IV end products.

Application areas of the OMNI plastic recycling line

The OMNI plastic recycling line is extremely versatile and suitable for a wide range of different polymers in various forms, such as film or fiber scrap. With a strong focus on efficient processing steps that are as short as possible, different material batches can be processed by the plastic recycling line and changed flexibly.

The application areas of OMNI plastic recycling machines are diverse and include the processing of waste from bottles, trays, injection-molded products, cups, blow-molded parts, thin film, stretched film, fiber, filament, fine materials, etc.

OMNI plastic recycling lines are suitable for processing various materials, including PET, PA, PP, PS, LDPE, HDPE, LLDPE and many more.

Efficiency and economy of OMNI plastic recycling lines

With its OMNI plastic recycling lines, Gneuss has launched a plant concept that pushes the previous limits of economic and technically feasible recycling. This applies particularly to the closed-loop recycling of food packaging and the recycling of textiles.

A key feature of OMNI plastic recycling machines is the optimal matching of all technological components to the recycling process. Thanks to many years of recycling experience, Gneuss can draw on a large number of patented and highly efficient solutions, which together enable unprecedented performance of the plastic recycling lines. Super-clean recycling qualities can be achieved in a single process step.

Advantages of the OMNI series:

- Compact design, small space requirements

Due to their compact design, the OMNI systems require little space and can therefore usually be integrated into existing premises, which has a positive effect on investment costs.

- Short residence time

The short residence time in the system largely avoids thermal damage, so that the chemical properties of the recycled material hardly differ from virgin material. Material changeovers are possible within minutes, so that production interruptions can be reduced to a minimum.

- High flexibility

The fully automated control of vacuum, extruder, metering, degassing residence time and filter change ensure on the one hand a consistently high quality of the recycled material and on the other hand enable the operator to use flexible and more cost-effective input materials.

- Low energy consumption

The compact design and short residence time result in low energy consumption. Each input to the extrusion process is designed to be usable for the following process step. This significantly reduces the electricity, gas consumption and CO2 footprint of the recycling process.

- High (super-clean) decontamination performance, even suitable for food contact

In a single extrusion step, harmful contaminants can be removed so thoroughly that the repelletized material can be used in contact with food. Various regional approvals for PET, PS, HDPE, LDPE, and PP are available.

Do you need more detailed information? Request our brochures or technical reports now!

Request