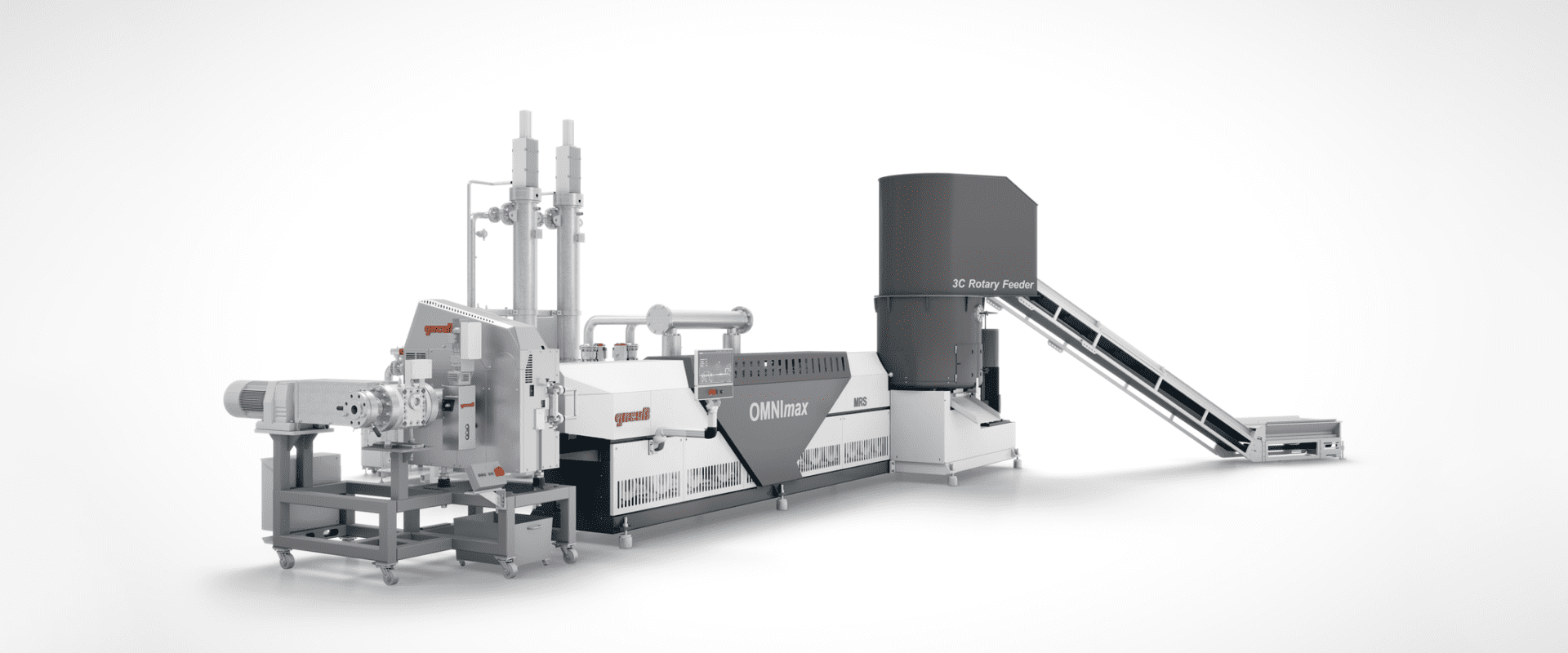

OMNImax Recycling System

The OMNImax Recycling System features a new 3C Rotary Feeder, an MRS- or MRSpure Extruder, a fully automatic melt filtration system RSFgenius and an Online Viscometer VIS.

The OMNImax enables super-clean recycling and is suitable for degassing, cleaning, decontamination, odor reduction, filtration and homogenization. It is primarily used for recycling film waste, post-consumer trays or cups, and for highly demanding degassing applications. The OMNImax is also used for tasks in the field of odor reduction.

Typical applications:

- Polystyrene (PS)

- Polypropylene (PP)

- Polyethylene (PE)

- Polyester (PET)

- Polylactides (PLA)

- Polyamide (PA)

3C Rotary Feeder

The newly developed 3C Rotary Feeder makes it possible to use low bulk density materials without any external processing steps. A conveyor belt feeds shredded reclaim material into the hopper, where a fast-rotating disc with knives cuts, compacts and pre-conditions the material. The knives add energy into the material and start the heating and degassing process before the material is automatically fed into the extrusion system.

Extrusion system

Depending on the application, the OMNImax series uses either a modified MRS extruder with a longer multiple screw section or an MRSpure. As a continuation of the OMNI series, the MRS extruder used in the OMNImax has an extended multi-screw section, which ensures efficient and gentle degassing of the polymer at a lower absolute pressure. As with all OMNI recycling systems, the requirements for direct food contact are generally met.

The use of stable multi-screws in the extruder also ensures unique homogenisation of the melt.

The large polymer surface enables highly efficient decontamination, mixing and viscosity control, especially with polyester, thus achieving high-quality end products such as packaging films, strapping tapes or filaments.

For higher viscous polymers, a MRSpure recycling extruder is used, with a melting extruder installed upstream of the multiple screw section. Depending on the requirements, a single or twin screw extruder can be used for melting. The MRSpure is used e.g. in closed-loop recycling of HDPE bottle caps, HDPE milk bottles or LDPE waste.

| MRS Extruder | throughput rate | ||

| PET | 35 – 2.000 kg/h | ||

| PP + PE | 25 – 1.400 kg/h | ||

| PA | 28 – 2.000 kg/h | ||

| PS | 30 – 1.600 kg/h |

RSFgenius rotary filter

The patented Gneuss RSFgenius Filtration System is always used in recycling applications. This model operates with an integrated backflush system for self-cleaning for very demanding applications and highest quality requirements. The screens can be automatically reused up to 400 times and filter finenesses below 10 µm are possible.

Vacuum technology

Gneuss has developed vacuum systems for extracting volatile impurities, some of which have patented separation systems. Due to the efficiency of degassing in the extruder, the extraction capacity is considerably greater than with conventional systems, so that large quantities of volatile impurities can be extracted from polymers and separated by highly efficient and automatic systems. Gneuss offers roots pumps to achieve low absolute pressures with corresponding low-maintenance and intelligent separation devices.

Online Viscometer VIS

The OMNImax recycling system also includes an online viscosity measurement system if required that enables precise measurement of the melt viscosity. Using a high-precision, high-conveying gear pump, a small partial flow of the polymer melt is diverted from the main melt channel and then forced through a precisely manufactured slotted capillary. The viscosity measured there is directly related to the molecular chain length, on which in turn the mechanical properties such as tensile strength and stiffness depend. Quality assurance can be improved by recording and storing this data through the viscometer.

Advantages of the OMNImax:

- all kinds of input material can be processed, including waste with low bulk densit such as fibre or biaxially oriented film

- highly flexible: all kinds of materials can be processed, such as PS, PP, PE, PET, PLA, PA

- super clean recycling technology: food contact compliance – even for post-consumer input materials, odour reduction

- minimised residence time, gentle processing and highest quality products

- closed recycling loop – no downcycling

- energy efficient, compact lines

Technical options

- Direct adaptation to sheet, strapping tape or fibre

production lines (no need for the intermediate step of

pelletising) - Blending of additives (in pellet or liquid form)

- Highly efficient, process-constant fine filtration

- Individually configured feeding systems, including the

Gneuss 3C Rotary Feeder

Do you need more detailed information? Request our technical reports and brochures now!

Request