PET bottle to bottle recycling – PET bottles reprocessed to the highest quality

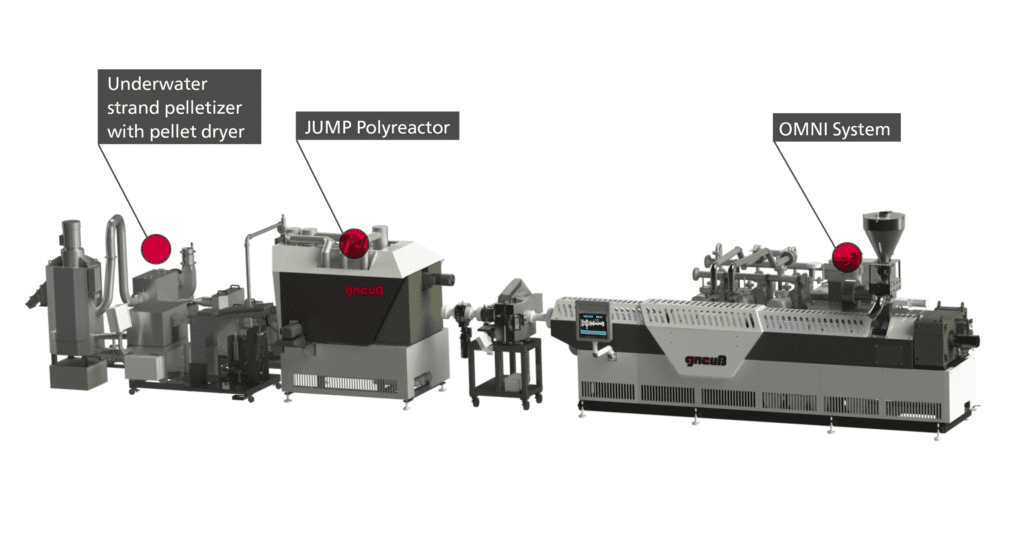

Gneuss pelletising lines produce excellent quality pellets, suitable for processing to food contact products thanks to the MRS extrusion process. The OMNIboost series is a PET recycling system that has been developed by Gneuss specifically in order to recycle polyester waste for applications with high viscosity requirements. The main areas of application are PET bottle to bottle recycling as well as the recycling of polyester waste with widely varying input viscosities, e.g. the recycling of fiber waste.

PET bottle recycling: technical options

- Underwater pelletizing (amorphous, spherical pellets)

- Underwater strand pelletizing (amorphous, cylindrical pellets)

- Strand pelletizing in an open water bath (amorphous, cylindrical pellets)

- Direct crystallisation

- JUMP reactor

- Continuous SSP with consistent in- and output quality

- Discontinuous SSP with varying qualities

The MRS extruder processes undried untreated PET bottle flake directly into pellets. The polymer melt is intensively and rapidly exchanged in the multiple screw section of the extruder. The huge surface area is exchanged at an unparalleled rate so that contaminants are efficiently evaporated out of the melt. A letter of Non-Objection (LNO) from the US food safety authority underlines the decontamination efficiency of the extrusion system. If a JUMP reactor or a downstream solid state polymerization system (SSP) is used in order to boost the intrinsic viscosity (IV), this can be specified far shorter than otherwise necessary as the extruder has already carried out the decontamination of the bottle flakes. The end product is of particularly high quality with regard to transparency and yellowness.

Advantages of Gneuss recycling lines for PET bottle to bottle recycling

Gneuss systems for PET bottle to bottle recycling offer numerous advantages for sustainable and high-quality recycling:

- Decontamination of volatiles, oils and odors

- Food contact compliance (US, Europe and other local certifications as well as from major global brand owners)

- Extraction of residual monomers

- Uniform, homogeneous pellets

- Amorphous, crystallized or highly viscous crystallized pellets

- Constant, adjustable IV Level

- Effective dispersion of fine particles

- High transparency, low yellowness index

- Major energy savings

Various international approvals confirm the high cleaning efficiency even for direct contact with food.

Publication

PET in Rotation

Kunststoffe international 10/2011

PDF-Download (920 KB)

Do you need more detailed information? Request our technical reports and brochures now!

Request