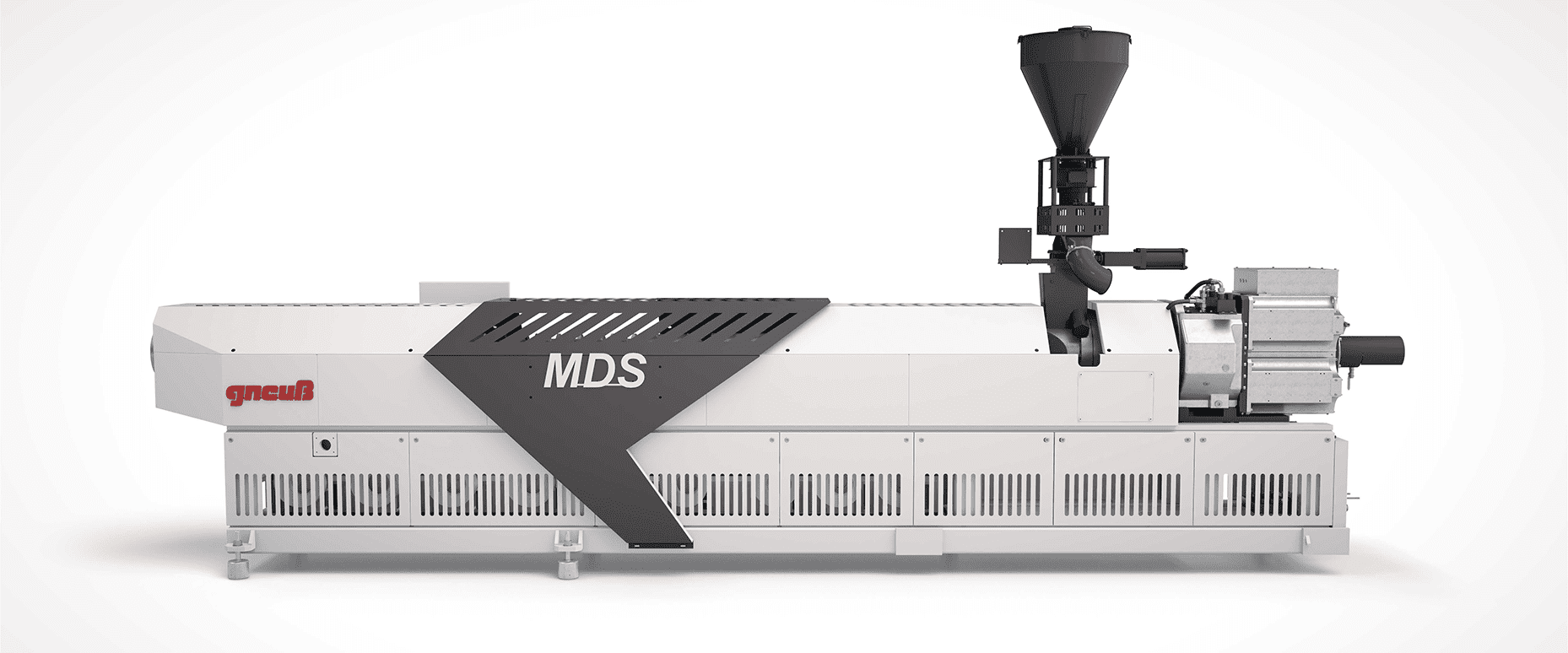

The MDS extruder

The new and patented MDS extruder from Gneuss is used for a variety of recycling applications. It is characterized by changing diameters of the screw and barrel, as well as a new type of interaction between energy input and degassing. Thanks to its robust design, the MDS is particularly suitable for recycling applications. The highly efficient degassing enables the production of outstanding qualities when processing PET, PA, PLA, but also and especially polyolefins such as HDPE or LDPE. With high-viscous polymers, gentle treatment at low shear rates is important, as high shear rates can destroy the long molecular chains. The multidimensional screw diameter enables optimum melting performance and degassing results while operating with low shear rates.

Design of the MDS extruder

The basic concept of the MDS extruder (Multi Dimensional System) is to thermally charge the melt in a very short time before it enters the degassing zone and thus to achieve an increased degassing effect under vacuum. This is achieved by widening the screw diameter in the metering zone with an immediately following long, deep-cut degassing zone with a similarly widened screw diameter. As a result, the optimum combination of energy input and degassing results in a highly efficient degassing performance with gentle melt treatment. The material charged in this way is instantaneously degassed. Thanks to its extremely robust and flexible single screw design, the system is ideal for the high-quality recycling of polymers such as PP, PET, PS, PA, HDPE, LDPE and many more.

For more extrusion systems, see the MRS Technology (single screw extruder with Multi Rotation System) and the MRSpure recycling extruder.

| MDS Extruder | Throughput rate | ||

| PET | 35 – 2.000 kg/h | ||

| PP + PE | 25 – 1.600 kg/h | ||

| PA | 28 – 1.900 kg/h | ||

| PS | 39 – 1.500 kg/h |

Advantages of the MDS extruder:

- Extremely robust

- Flexible design

- Wide range of materials

- High degassing performance

- Gentle processing

- Outstanding quality standards

Technical Options

- Pre-degassing to optimize the IV value of polyesters before LSP

- Removal of odors during recycling of many polymers, especially polyolefins