Gneuss’ patented screen changers and filtration systems

As a well-known manufacturer and supplier of patented screen changers, Gneuss looks back on many years of experience in melt filtration. With lots of expertise and technical know-how, we offer state-of-the-art solutions for the successful removal of impurities and contaminants from polymer melts. Gneuss’ innovative products ensure reliable filtration and provide improved product quality and increased efficiency of production processes, while also protecting downstream equipment.

Innovative screen changers of excellent quality

Gneuss offers a wide range of filter models specifically tailored to different applications in the plastics industry. From fine filtration to the removal of coarse impurities, we supply customized filter solutions that meet your company’s individual requirements and processes:

Screen changers

process constant

pressure constant

self-cleaning

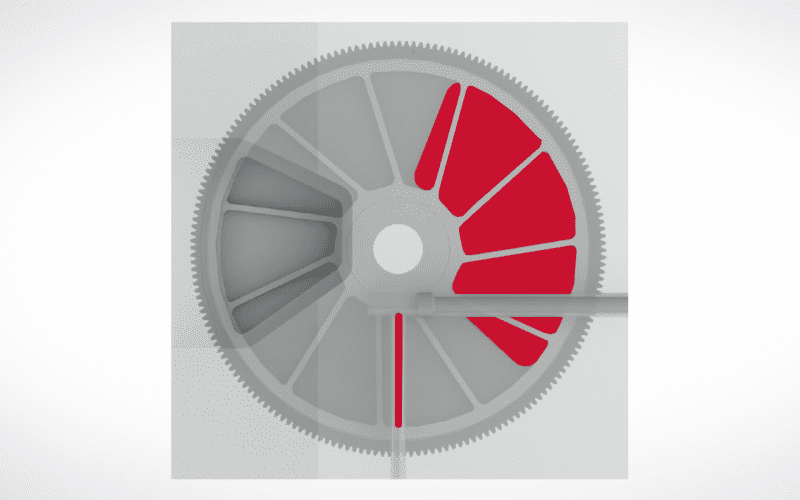

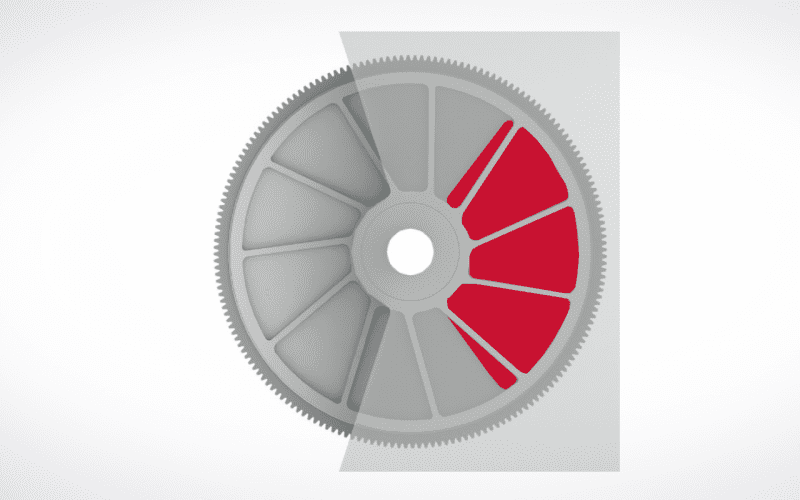

RSFgenius Series

Patented Rotary Filtration System with back-flushing piston for demanding applications and highest quality requirements. These screen changers offer absolute process and pressure consistency with high flexibility and fully-automatic operation with integrated self-cleaning.

process constant

pressure constant

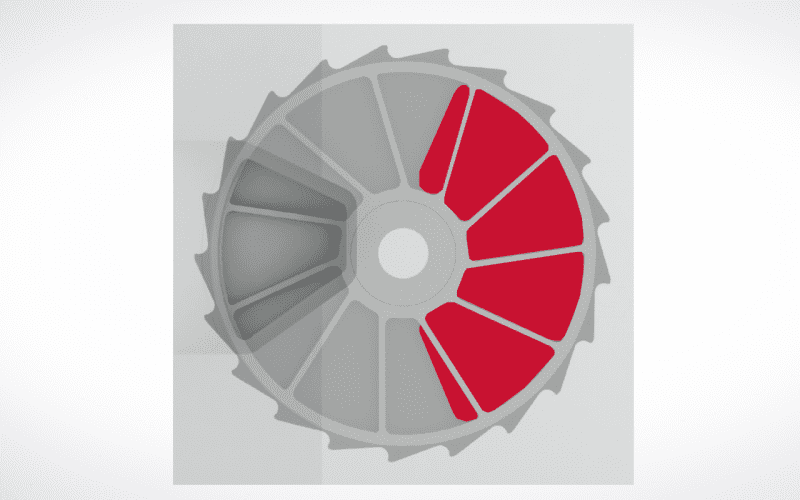

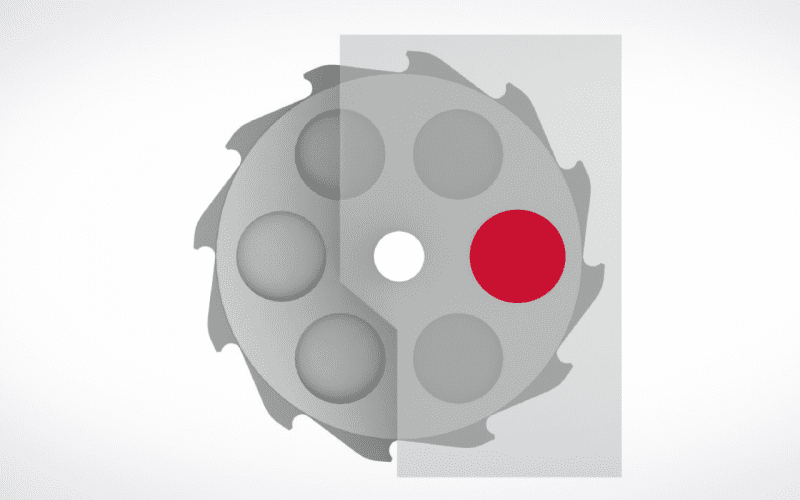

SFXmagnus Series

Patented, compact Rotary Filtration System with very large active screen surface within a remarkably compact unit, suitable for almost every application. These screen changers offer absolute process and pressure consistency.

process constant

pressure constant

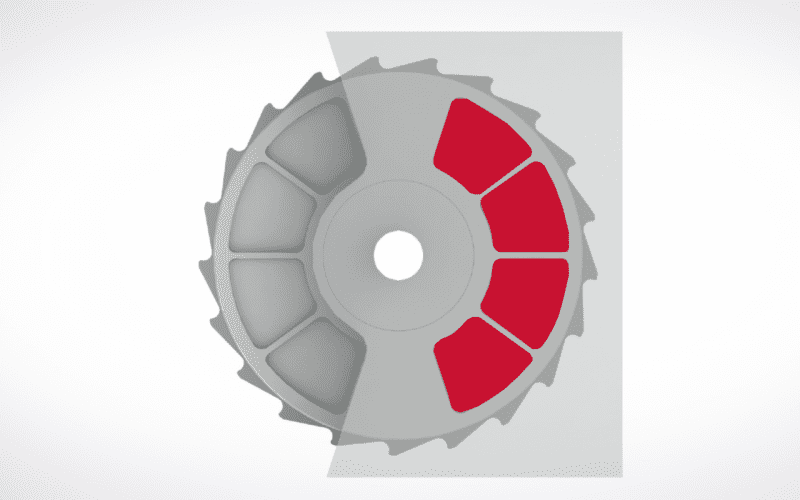

SFneos Series

Patented Rotary Filtration System designed specifically for thermally sensitive applications with special requirements with regard to rheology. Quick and easy screen change without production disturbance and with constant product quality, process-constant and pressure-constant operation.

process constant

KSF Series

Compact screen changers for applications with frequent material and/or colour changes. Quick and easy screen change during running production, continuous operation.

process constant

CSFprimus Series

Simple screen changers, which provide a large active screen area, based on the proven concept of rotary technology. They are preferably used where a large screen area must be available and screen changes can be synchronized with batch or roll changes.

Gneuss’ screen changers for a wide range of applications

Gneuss’ innovative screen changers are used in a wide range of applications and provide effective filtration for many materials and processes. Whether processing virgin, reclaim or special plastic compounds, our filtration systems enable a reliable removal of impurities and particles to improve the quality of end products and protect downstream equipment.

Applications

More products

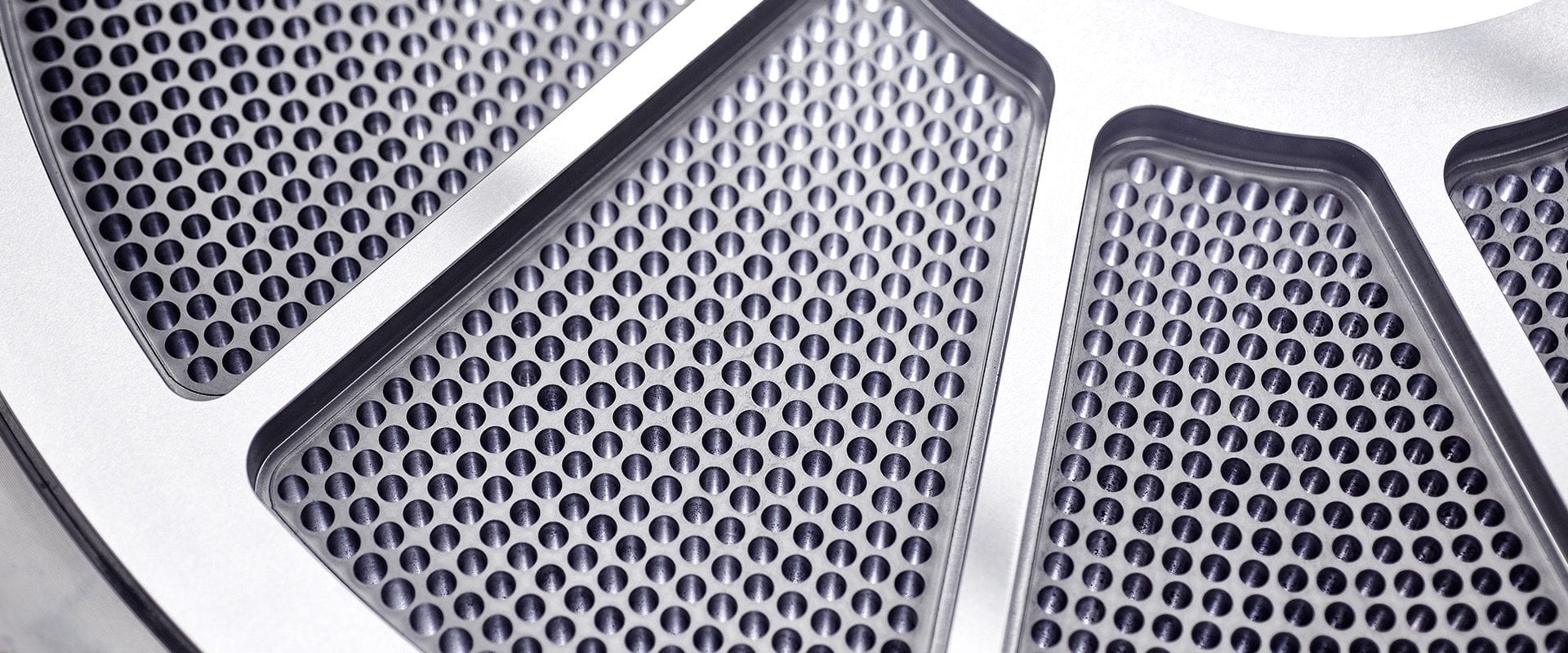

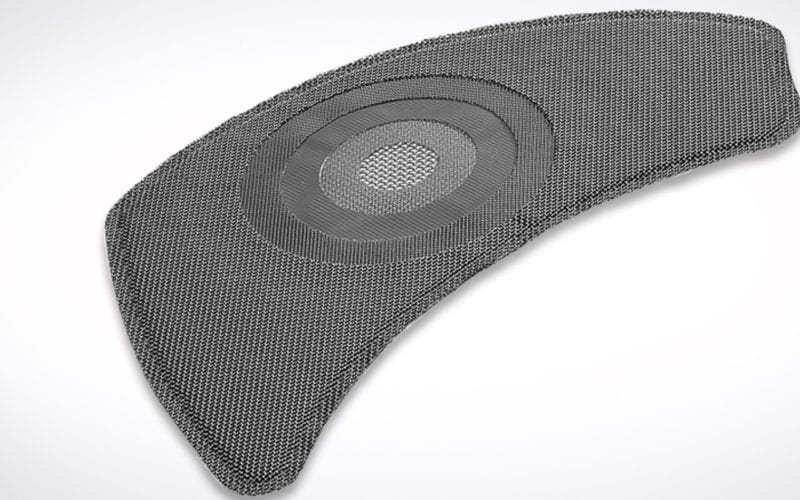

Filter Elements

For the production of high quality plastic melts, Gneuss not only supplies tailor-made filtration systems, but also filter elements optimized for each material type and application.

Diverter Valve

The diverter valve GAV is a rugged and competitively priced discharge valve. Its advanced design combines ease of use with excellent line availibility.

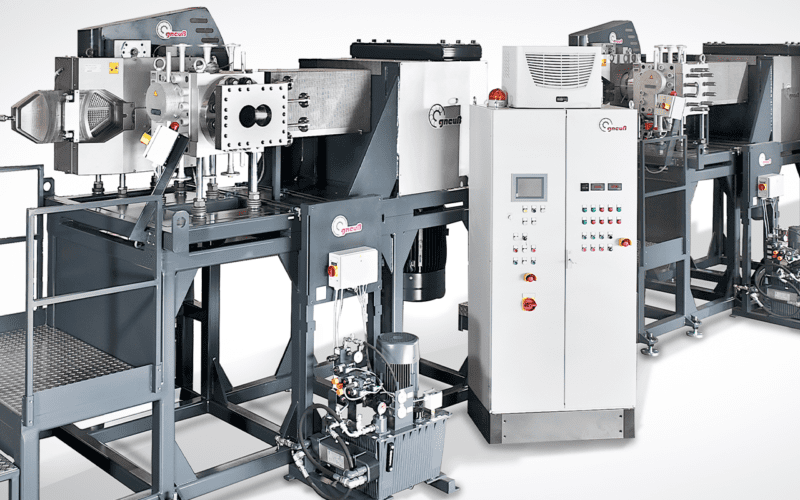

Complete systems

Gneuss offers not only Filtration Systems, but also complete solutions, e.g. rheologically optimized melt filter-pump combinations. One focus of our work is the processing technical optimization of the integration of the individual components as well as of the line concept.

Innovative screen changers for the highest filtration demands

Thanks to continuous research and development our screen changers are always state of the art and have been carefully designed to meet the highest demands of our customers. At Gneuss, our goal is to provide customized filtration solutions that optimize your production processes, reduce scrap rates and increase efficiency. Rely on many years of experience and expertise in filtration technology to take your plastics processing application to a new level of quality.

Do you need more detailed information? Request our technical reports and brochures now!

Request