Typical applications are e.g.:

Packaging sheet, insulation sheet, decoration sheet, thermoforming sheet

- Typical materials: PS, PE, PP

- Common throughputs up to 2.000 kg/h

- Filtration finenesses down to 100 µm

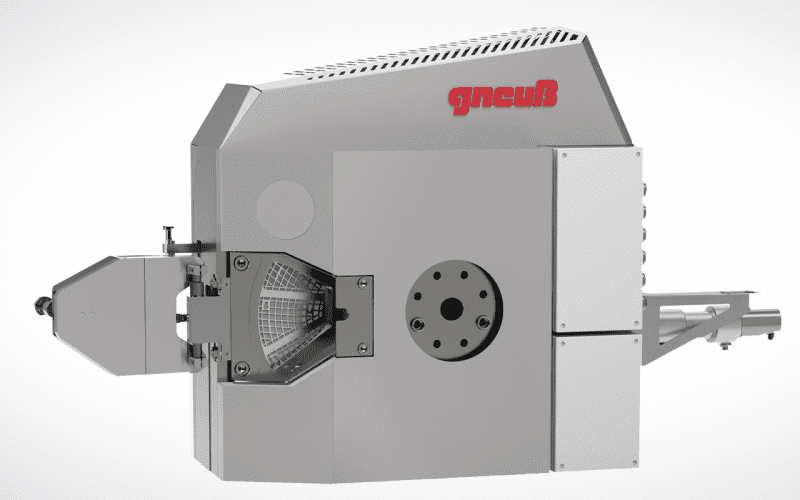

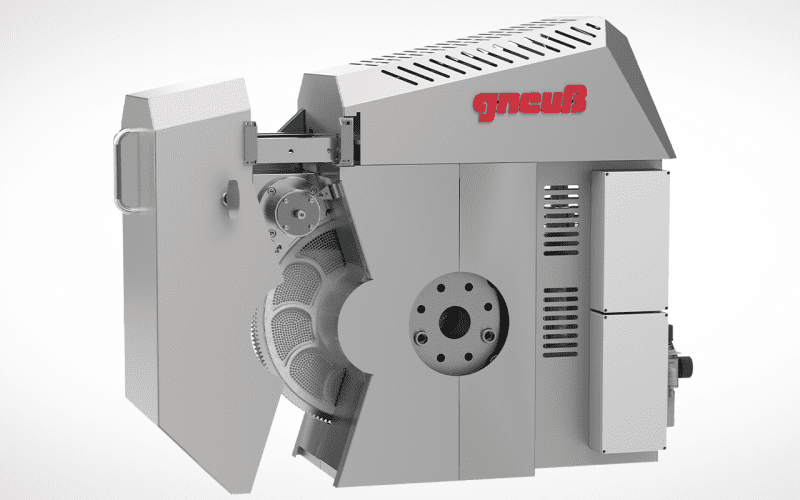

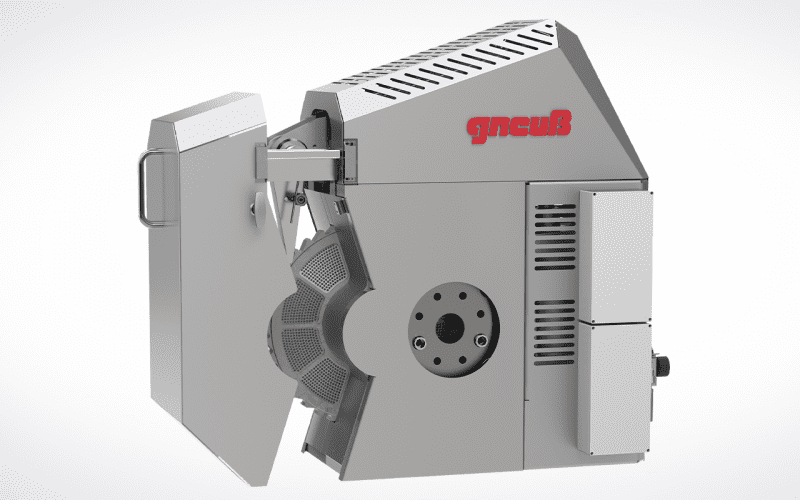

In foam sheet manufacturing – due to special production conditions – the filtration system, besides guaranteeing a reliable removal of solid and soft particles, must fulfill many additional requirements. Permanent pressure-consistency is very important to create a uniform and homogeneous cell structure and to avoid melt expansion during screen changes. Moreover, the filtration system must exclude the possibility of a gas leakage. For these applications Gneuss Filtration Systems offer tailor-made solutions and make continuous cost reduction in the production process, combined with top product qualities, possible.

The advantages of Rotary Filtration

- Constant foam structure

The pressure-constant mode of operation of the filtration system makes a constant foam structure possible. This not only guarantees constant product properties, but also ensures trouble-free downstream processing. - Minimum thickness tolerances

The process consistency of the Gneuss Rotary Filtration Technology reduces product tolerances and therefore leads to material cost savings and very good film flatness. - Maximum line availability

Fully-automatic screen changes without production disturbances and interruptions ensure maximum line availability. The RSFgenius and the SFXmagnus even offer a fully-automatic operation. - Reduced material costs due to greater use of reclaim

Gneuss Filtration Systems make it possible to process a greater amount of reclaim, without impairing the product quality. This leads to reduced material costs. - Safe and clean screen changes

Gneuss Filtration Systems make safe and clean screen changes possible, thanks to the pressure release of the emerging cavity and the unique sealing technology.