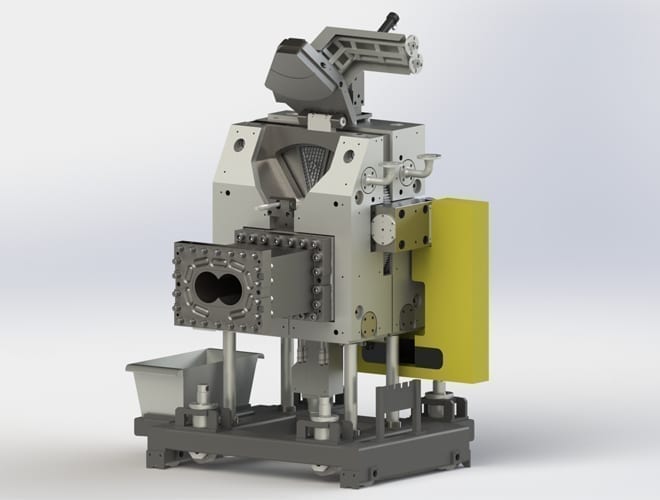

Variable melt channel for rheologically optimised connection directly to a twin-screw extruder as well as to a melt pump.

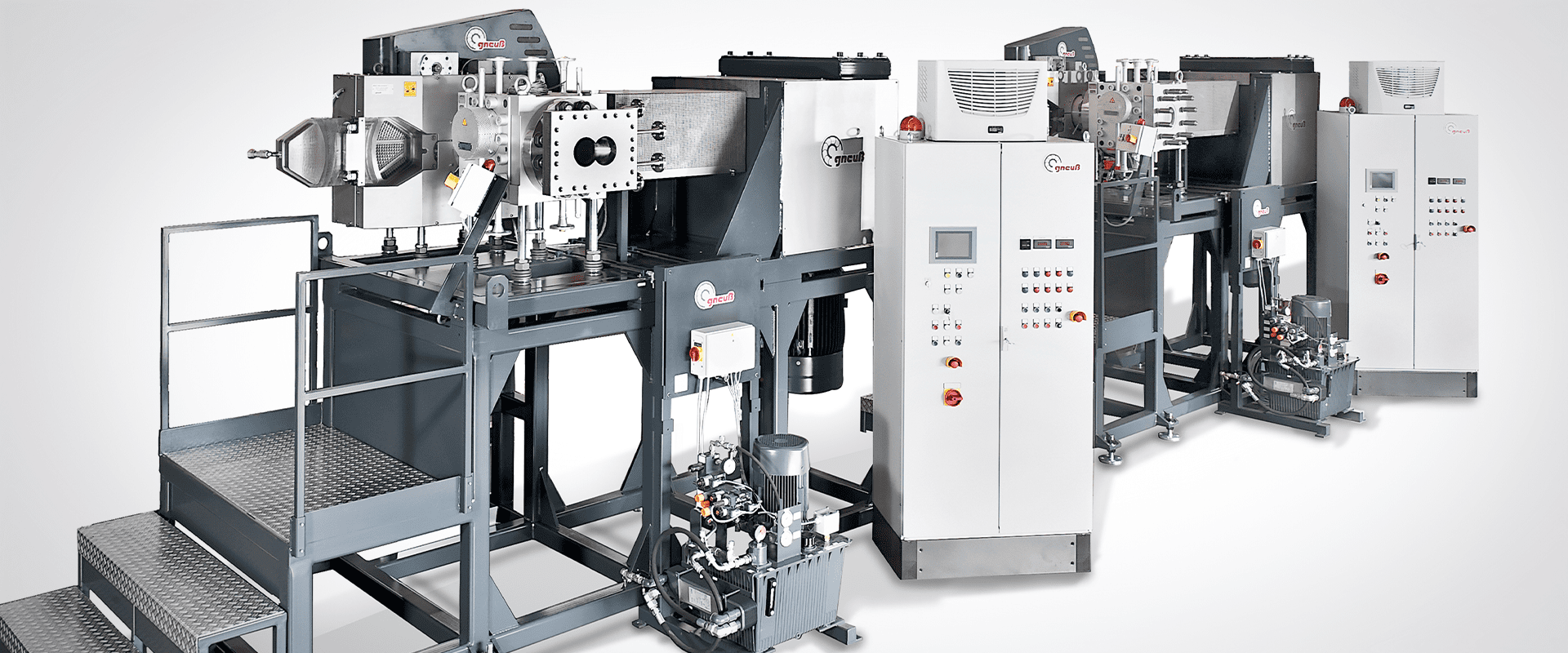

Complete solutions for complex tasks

Gneuss offers not only Filtration Systems, but also complete solutions, e.g. rheologically optimized melt filter-pump combinations. One focus of our work is the processing technical optimization of the integration of the individual components as well as of the line concept.

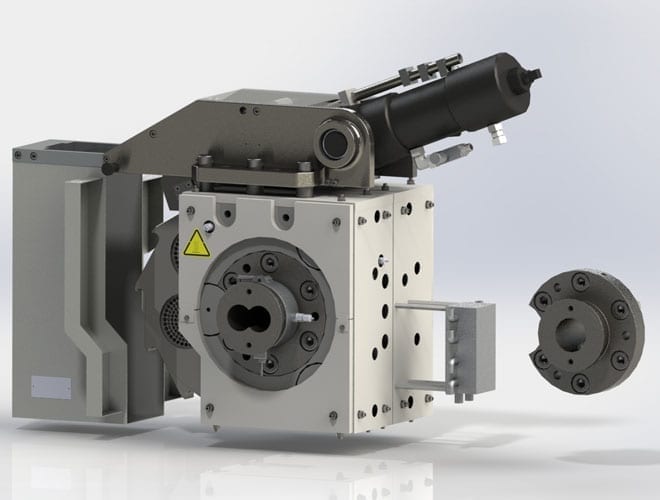

Example: pump-filter combination

Gneuss melt filter-pump combinations are characterized by extremely short melt channels and thus by a minimized melt dwell time. The individual components are harmonized, so that integration is possible without complex adapter flanges. The transitions in the melt channel are rheologically adapted to the neighboring unit, so that the channels are free from dead spots and the melt flow is homogeneous at every point. Simple handling and operation are always guaranteed.

Example: filtration with integrated strand die

Especially in the manufacture of masterbatch and pellets, where color and material grades are changed frequently, a rheologically optimized melt channel is necessary for reasons of self-cleaning, in order to prevent time consuming cleaning of the melt channels. Additionally, quick and easy access to all the parts in contact with the melt must be possible. You can benefit from Gneuss’ decades of experience in this area.