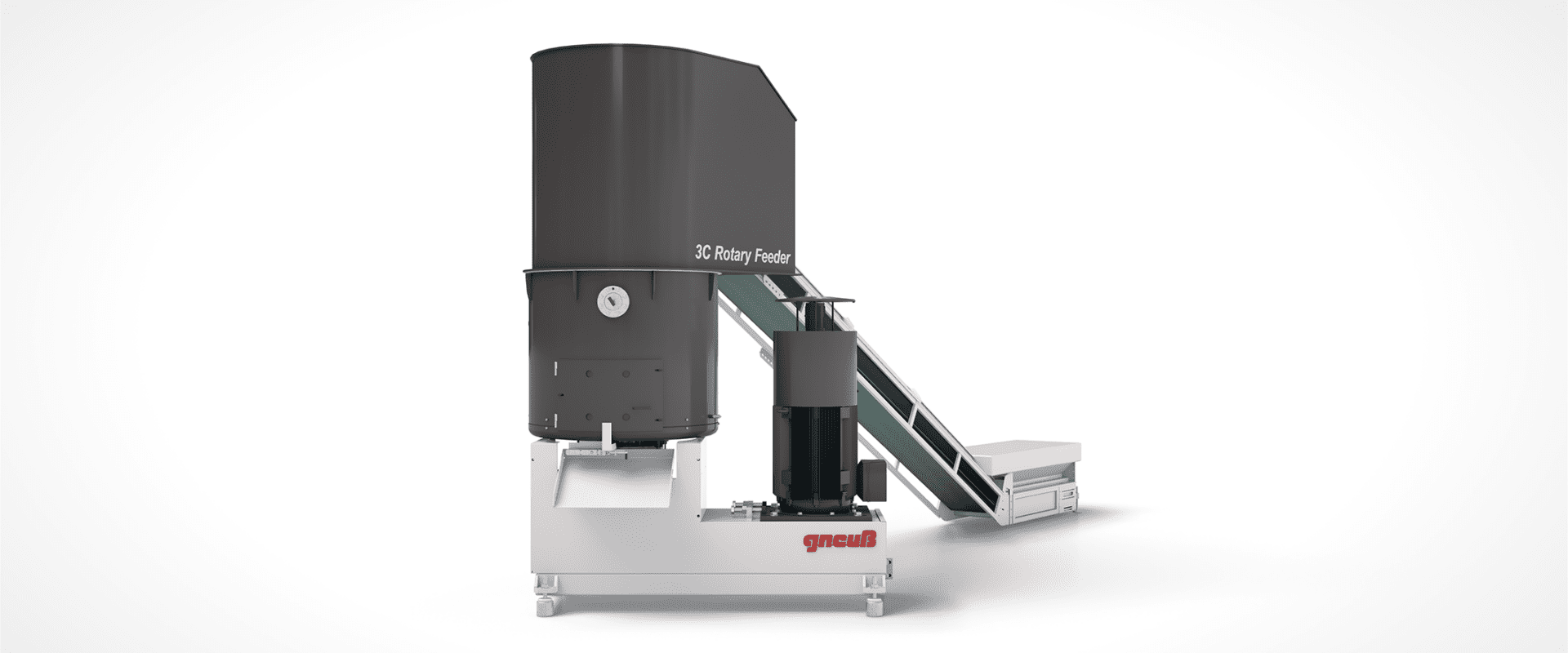

3C Rotary Feeder

To process materials with a low bulk density without external, upstream processing steps, Gneuss offers a system consisting of an optional shredder, a conveyor belt and the 3C Rotary Feeder. The Rotary Feeder creates ideal conditions for the subsequent extrusion process by optimally cutting and compacting the material.

Operating mode of the 3C Rotary Feeder

In the shredder, the material is pre-shredded if necessary and then fed to the 3C Rotary Feeder in a timed sequence by the conveyor belt. A disk with cutting elements rotates in the drum of the 3C Rotary Feeder, cutting, compacting and heating the material. As a result of the energy supply, the surface moisture is removed from the material before the extrusion step, thus helping the plasticizing process. The material transfer between the 3C Rotary Feeder and the extruder is fully automatic and results in consistent extrusion conditions even with fluctuating input qualities.

3C Rotary Feeder offers versatile material processing

A very wide range of materials can be processed with the Gneuss 3C Rotary Feeder, as the combination of “cutting”, “compacting” and “conditioning” before the MRS extrusion process creates a very large process window. The spectrum of different types of materials ranges from foamed PS blocks to fiber bales. In conjunction with the unique MRS Extruder this results in an ideal solution for plastics recycling.

Do you need more detailed information? Request our technical reports and brochures now!

Request