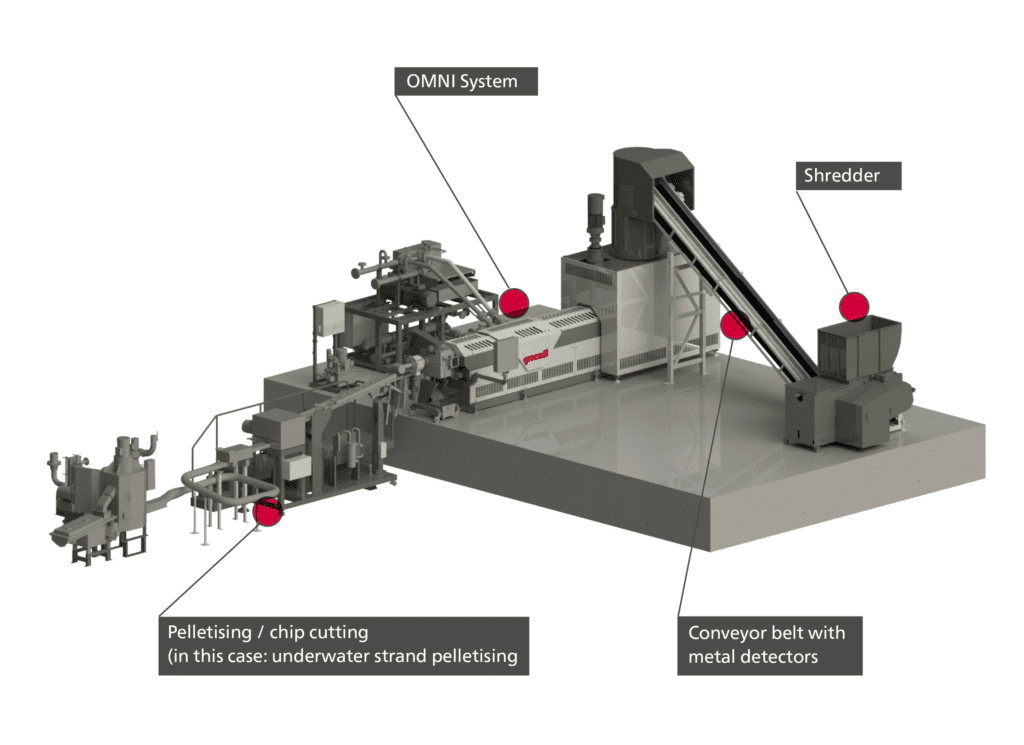

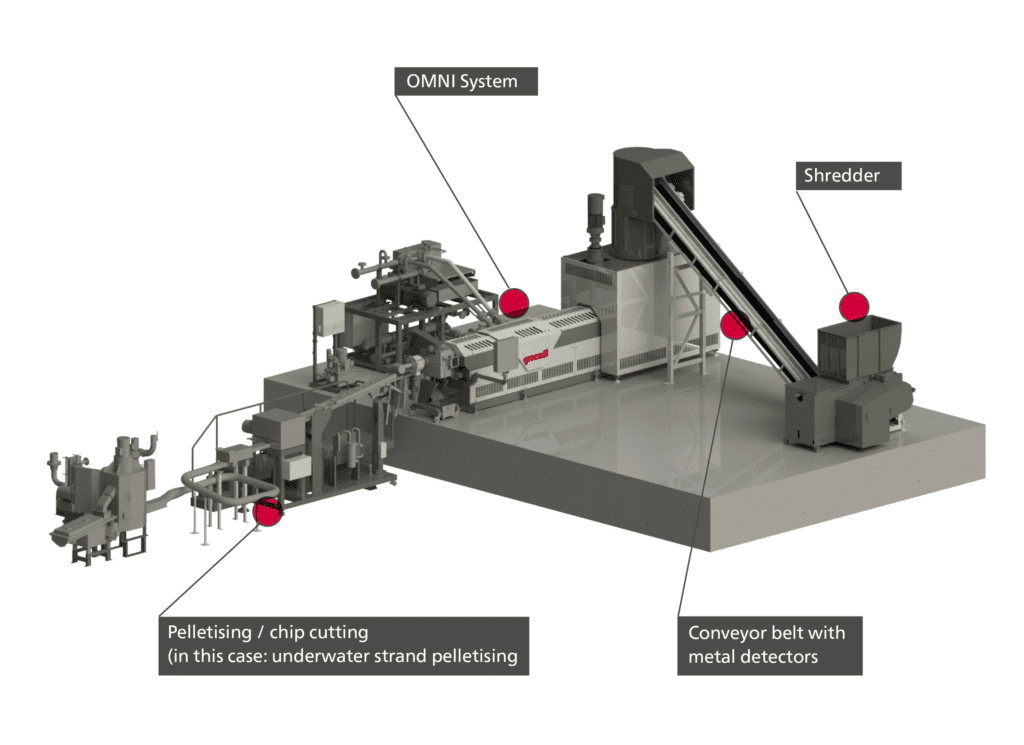

The light bulk density production waste from fibre, film and start up waste are taken in tangled, non-flowing form and fed into a shredder where they are size reduced to a form which can be fed to an extruder. The material is transported by means of a conveyor belt via a metal detector into an intermediate buffer container with an agitator. From there, the voluminous material is fed by means of a dosing auger and crammer feeder into the extruder. The material is melted, devolatilised and decontaminated in the extruder. Volatile contaminants such as water or oils are extracted. Solid contaminants are extracted from the melt by the Rotary Filtration System. After pelletizing, the pellets / chips which have been purified from volatile and solid contaminants, can be used to replace virgin material in the manufacture of film, sheet, fibre, strapping tape etc..

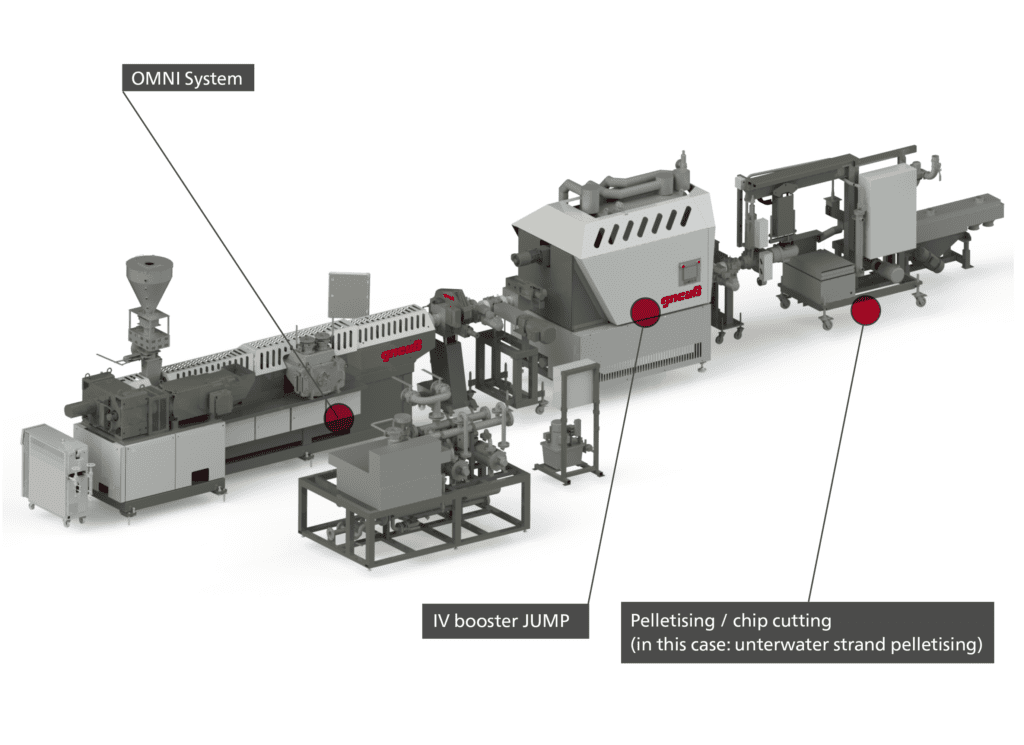

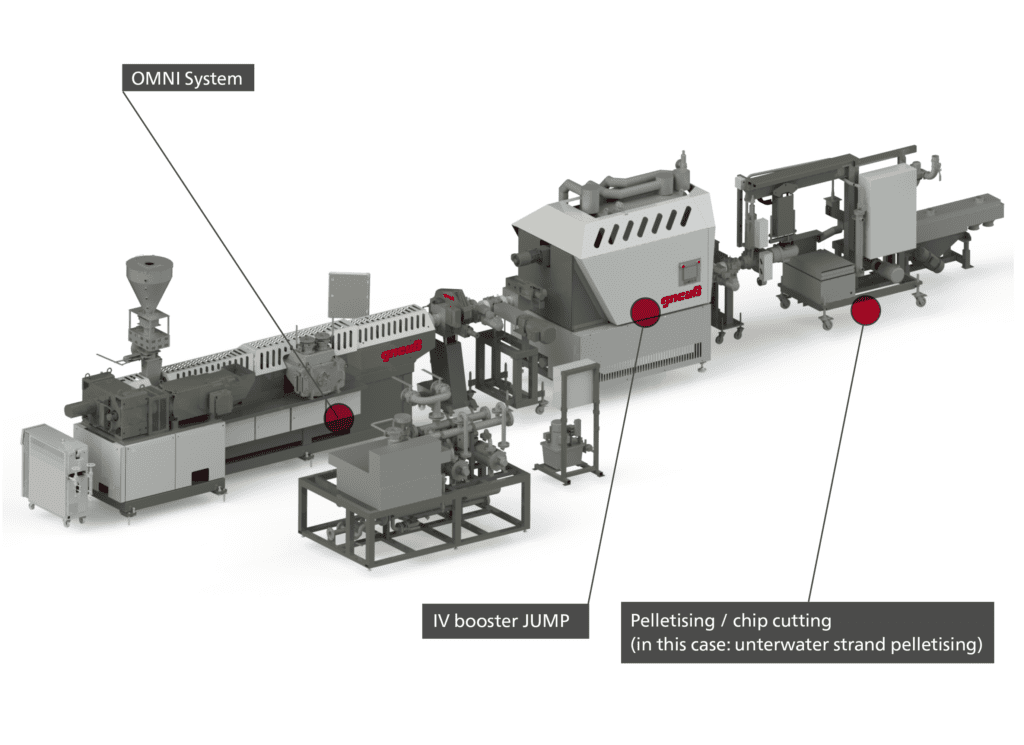

The starting point is production waste from fibre, film and start-up lumps. These are size-reduced and if necessary agglomerated and fed to the MRS extruder through a metal detector where they are melted and devolatilised – volatile contaminants such as absorbed or surface water, spin finish oils or other processing oils are extracted. Solid contaminants are extracted with the Rotary Filtration System and by means of a booster pump, the melt PET is fed into the liquid phase IV boost system, JUMP. Agitating and mixing devices within the JUMP reactor also achieve – under a deep vacuum – high polymer melt surface exchange rates and so achieve a set IV. The viscosity is adjusted by means of the Online Viscometer in combination with the process control system. The polymer melt is pumped out of the vacuum, through a further Rotary Filtration System for fine filtration and is then pelletised.