Ensuring High-Quality Plastic Melts with Gneuss Filter Elements

Highest quality demands on filtered plastic melts can only be met if filtration systems and filter elements are matched to each other based on expert knowledge. The use of Gneuss filter elements ensures consistently high melt and product purity.

During the filtration of plastics, filter elements in filtration systems are exposed to high stress such as alternating differential pressures and high temperatures. The impurities present during filtration can have a high abrasive effect in some cases, whereby stress is additionally increased by partly corrosive plastics. However, in order to guarantee the selected absolute filter fineness permanently, special techniques must be applied and observed in the manufacture of filter elements.

Highest product quality thanks to defined purity standards

Gneuss screen packs are available in nominal filter finenesses of 3 µm – 1,400 µm, offering the right solution for every application. The high-quality fabrics, which exceed the tolerance specifications of DIN ISO 9044:2001, can be cleaned of oils, greases and other impurities with the help of an ultrasonic basin.

Efficient combination of woven wire cloth

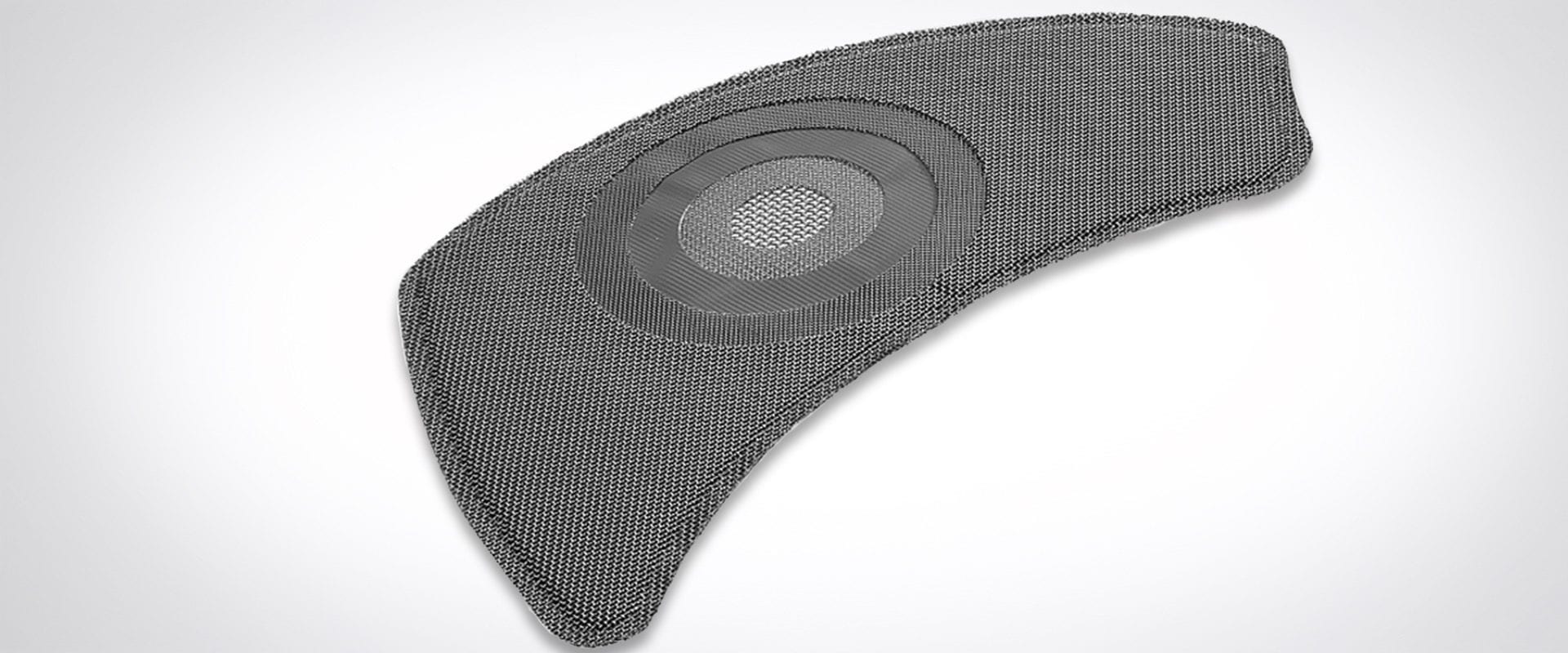

With the combination of square meshes and optimized Dutch weave, sufficient stability is achieved with optimum permeability at the same time. The efficient fabric combination offers the best back-flushing properties, enables fine filtration, high throughputs and rare screen changes.

Reinforced screen packs for back-flushing filters

Gneuss has developed a special back-flushing technology to implement fully-automatic filtration and reduce filtration costs. With this technique of partial high-pressure back-flushing, multiple use of the screens is possible. The screen packs for filtration systems with back-flushing are equipped with additional support layers which withstand the alternating high stress.

Demanding material selection and processing

Gneuss uses only high-quality stainless steel to counteract the many stresses within the filtration process. Due to its low carbon content, the steel also resists corrosive plastics and does not oxidize during prolonged storage. The material is approved for temperatures up to 600 °C and therefore withstands the high melt temperatures encountered. The increased yield strength of the steel also ensures sufficient stability during filtration.

Individual development and consulting for our customers

Gneuss screen packs cover the majority of standard applications. Customer-specific solutions can also be implemented on request. If you would like to optimize your filtration performance and quality, we will be pleased to help you with the analysis of the respective filter elements. If required, we can provide you with comprehensive test reports with further recommendations. Just contact us!

We can give you these guarantees,

- because we only use wire cloth of highest quality and specifications with a clearly defined selectivity, manufactured in accordance with quality standard ISO 9001:2015.

- because we only supply absolutely clean screens. This avoids that the melt purity is affected by new screens due to the fact that foreign particles or any other substances, such as oil, are introduced into the melt.

- because we use our many years of experience to design these special screen packs.

- because we give you professional and detailed advice on the use and exchange of the filter elements.