Gneuss Compounding Technology

Today, the standard method for introducing additives into polymers is with the additives in powder form. These are fed into the plasticized polymers via a side feeder on the compounding extruder. Normally, the side feeder is a small single or twin screw extruder. The main extruder is typically a co-rotating twin screw extruder in order to achieve good inclusion and dispersion of the polymer.

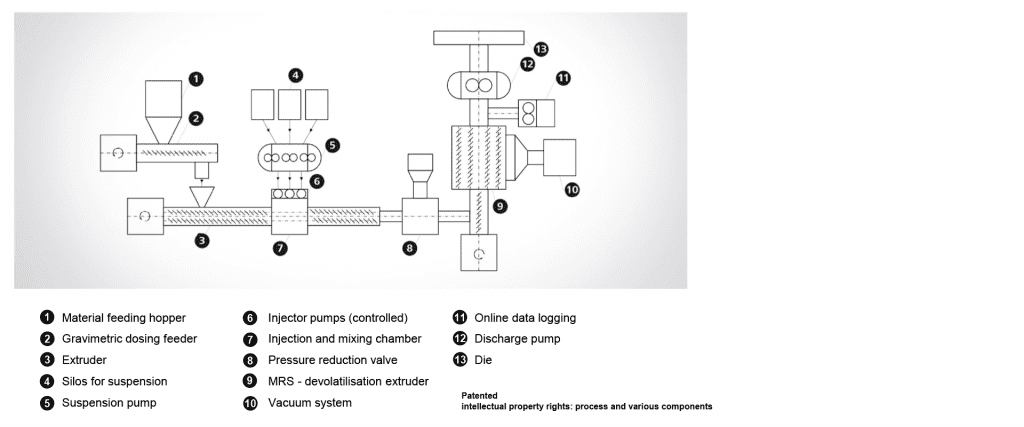

With the Gneuss compounding system, the additives are not introduced to the polymer in powder form, but with the help of a suspension, which contains extremely fine, agglomerate-free particles.

The suspension is introduced into the polymer melt by means of a special pump and a specially designed injection nozzle into a pressure and mixing chamber. The mixture of polymer and suspension can easily and immediately be thoroughly mixed, so that no agglomeration of the additives takes place.

In order that the liquid carrier of the suspsension does not negatively affect properties of the polymer, it is completely extracted within 6 seconds. This takes place in the Gneuss MRS extruder, which is located immediately downstream of the suspension injection point. The extremely high devolatilisation performance of the MRS extruder ensures that the liquid is efficiently extracted as a volatile. Additionally, the additives are gently distributed in the polymer, and extremely homogeneous dispersion is ensured.

Performance characteristics of the Gneuss Compounding Technology

- Introduction of small particles of all kinds (generally 1.000 to 2 nm) in polymers via a suspension, with negligible agglomerates.

Conformation with nano particle handling regulations regardless of the particle size - Extremely homogeneous distribution of all particles

- The polymer chains are practically uneffected by the introduction of the particles

- Several different suspensions can be introduced into the polymer simultaneously

- Also suitable for reactive extrusion

Publication

Cascade Extruder with Multiple Screw Devolatilization System for Compounding

Neither Shaken nor Stirred