Gneuss’ innovative extrusion systems for demanding applications

Gneuss’ extrusion systems offer new avenues for the reliable devolatilization and processing of polymer melts. They are characterized by high efficiency and performance, and are designed to ensure excellent product quality while optimizing energy consumption.

Extrusion Systems

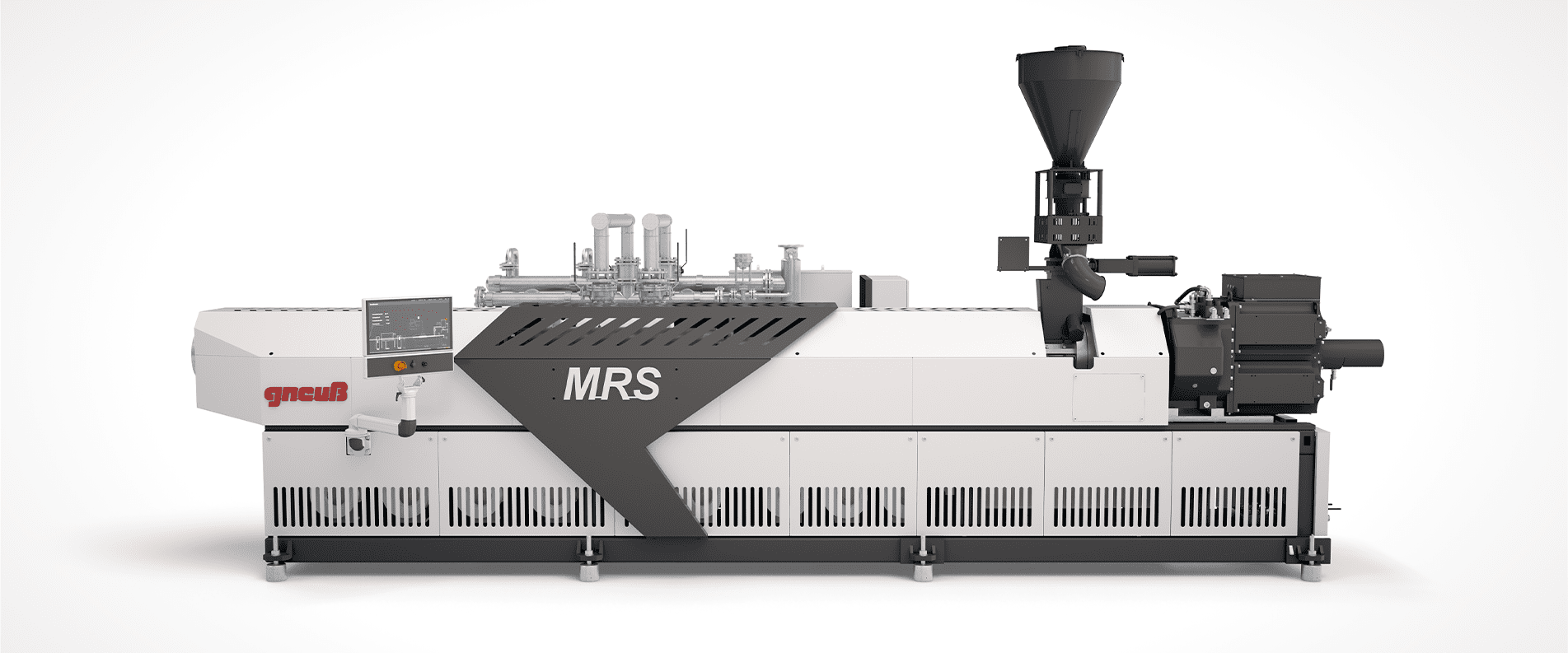

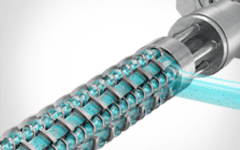

MRS Extruder

The patented MRS Extrusion System offers completely new possibilities with regard to the efficient degassing and extrusion of polymer melts.

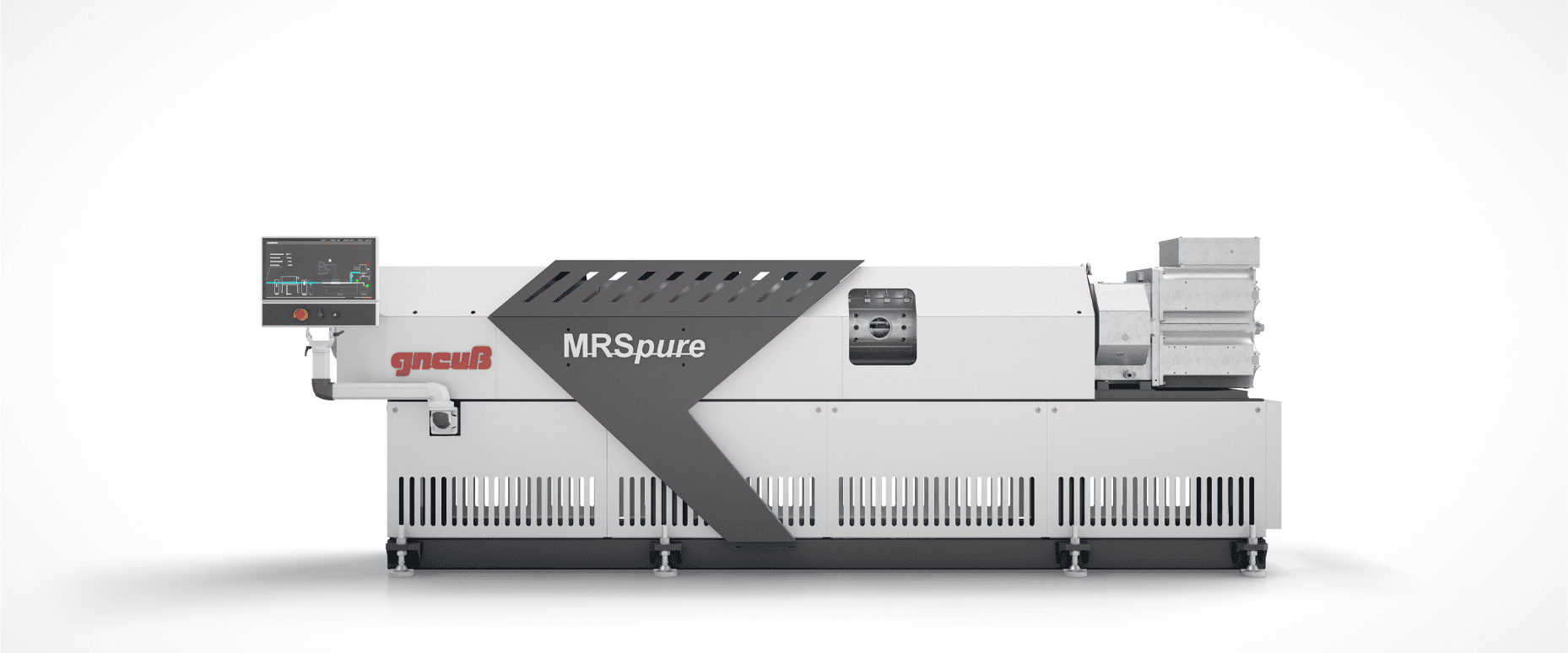

MRSpure Extruder

The MRSpure Extrusion System: plasticizing and decontamination in two process steps that can be independently optimized.

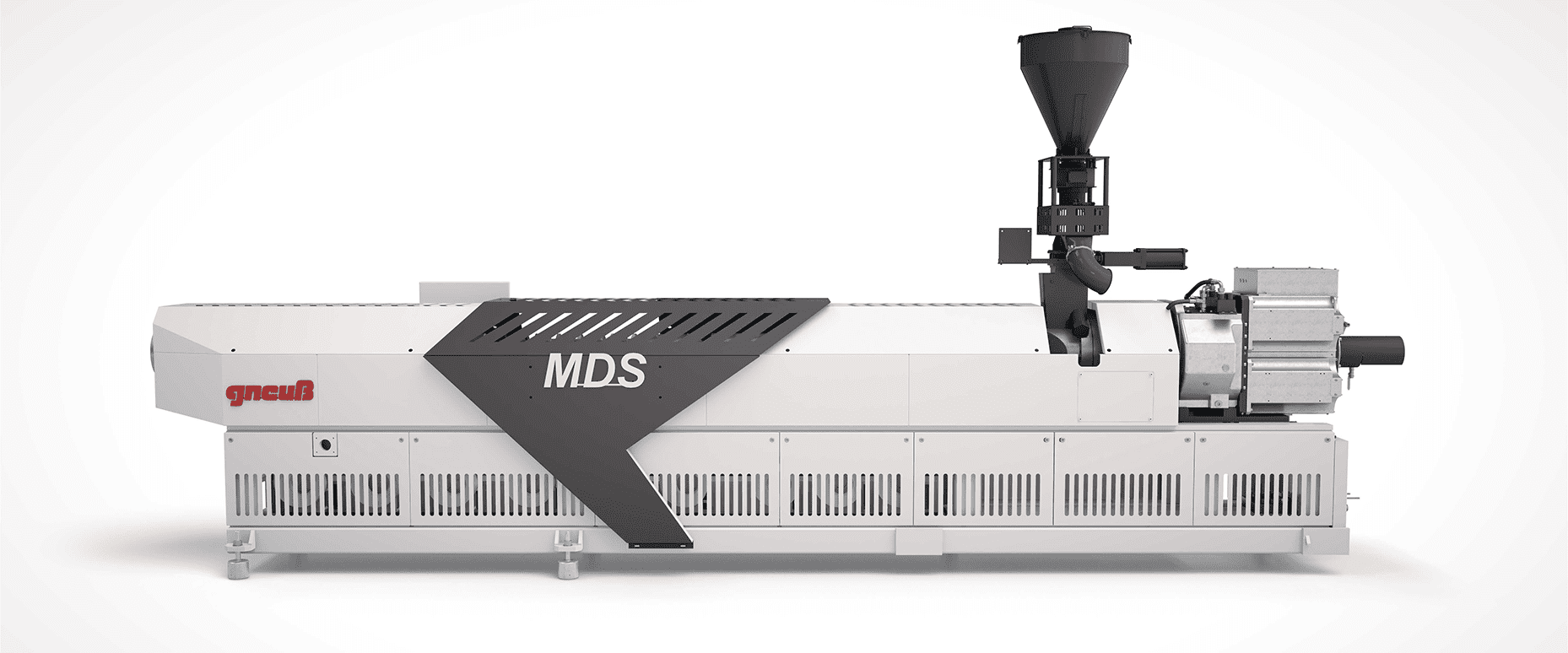

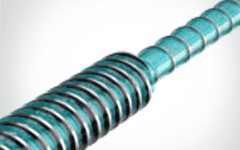

MDS Extruder

The MDS Extrusion System opens up new possibilities in single-screw degassing, especially for higher viscosity materials.

Quality through modern technologies

Gneuss specializes in developing innovative technologies to continuously improve the quality of extrusion and recycling lines and their components. By using intelligent systems and advanced control mechanisms, we enable sustainable and high-quality plastics processing.

MRS technology for devolatilization

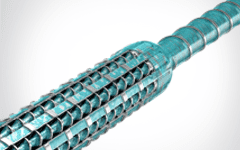

A key aspect of Gneuss’ extrusion systems is the MRS-Extruder (Multi Rotation System). This innovative technology offers many new possibilities for the efficient devolatilization and recycling of polymer melts.

MRS and MRSpure extruders include a multiple screw section to disproportionately increase the surface area and surface exchange rate of the polymer melt. In combination with a Gneuss vacuum system, this makes it possible to very efficiently remove gases and volatile components from the melt

Advanced control systems as well as state-of-the-art measurement technology, which ensure precise control of the extrusion process and guarantee high product quality and ideal process stability.

Focus on sustainability and energy efficiency

Gneuss extrusion lines are designed to minimize energy consumption and reduce any negative environmental impact. By using innovative extrusion technologies such as the MRS or MDS, as well as optimized vacuum systems and highly efficient Rotary Filtration Systems, the production process can be optimized to reduce material losses, pollutants, and save energy.

In combination with fully-automatic melt filtration systems and precise process control, the extrusion systems are able to produce high-quality end products from reclaimed materials. This contributes to the conservation of resources and supports a sustainable plastics industry.

Customer service worldwide

We are committed to excellent customer service and offer extensive support for the implementation and maintenance of our extrusion systems. Headquartered in Germany, with a subsidiary company in the USA, offices in Brazil and China, a cooperation partner in Japan and together with representatives worldwide, we have a global sales and service network that ensures that our customers worldwide have access to expert advice and technical support at all times.

Gneuss extrusion systems: outstanding performance due to continuous R&D

Continuous research and development enables us to introduce new technologies that further improve possibilities in plastics processing. With the goal of providing our customers with the best solutions, we are an industry-leading manufacturer of extrusion systems and a trusted partner for companies, offering the highest efficiency and quality in extrusion.

Do you need more detailed information? Request our technical reports and brochures now!

Request