High-Performance Filtration for Oriented Films

Typical applications are e.g.:

Packaging film, video tapes, capacitor film, adhesive tape

- Typical materials: PP, PS, PET, PA

- Common throughputs up to 6.000 kg/h

- Filtration finenesses down to 6 µm

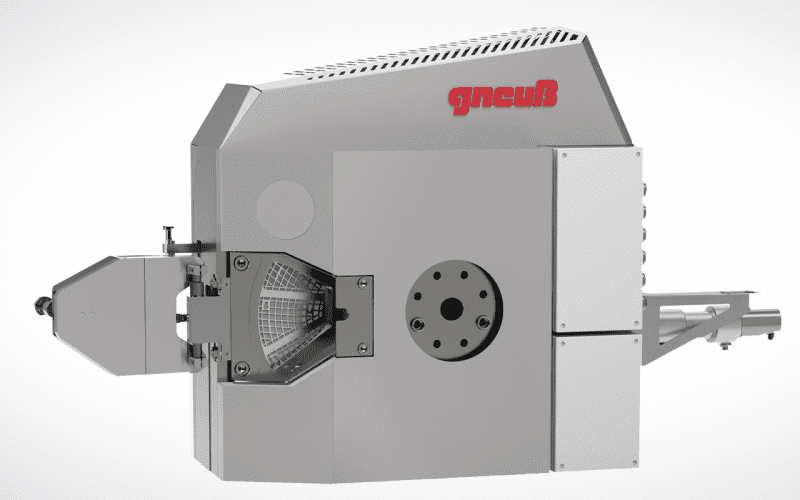

For the production of oriented film, a reliable removal of solid and gel-like particles and a fully-automatic filtration system, which operates pressure-constantly and without process interruptions, is very important. To avoid thermal damage or degraded material, the dwell time of the melt as well as the dirt cake in the filtration system must be kept very short. The RSFgenius and the SFXmagnus were specifically developed for these requirements. These systems make a continuous cost reduction in the production process as well as top qualities possible.

The advantages of Rotary Filtration

- Minimum thickness tolerances

The process consistency of Gneuss Rotary Filtration Technology reduces product tolerances and therefore leads to material cost savings and a very good film flatness. In particular the pressure-constant mode of operation of the filtration systems RSFgenius and SFXmagnus guarantee optimum qualities. - Maximum line availability

Fully-automatic screen changes without process interruptions and disturbances ensure a maximum line availability. - Top quality surfaces without fish eyes

The fully-automatic and process-constant mode of operation of the filtration systems makes using finer screens possible and thus leads to an improvement of melt and product quality. - Reduced material costs due to greater use of reclaim

Gneuss Filtration Systems make it possible to process a greater amount of reclaim, without impairing the product quality. This leads to reduced material costs. - Quality assurance

The fully-automatic as well as process-constant mode of operation stabilizes the production process and is therefore an important contribution to quality assurance.