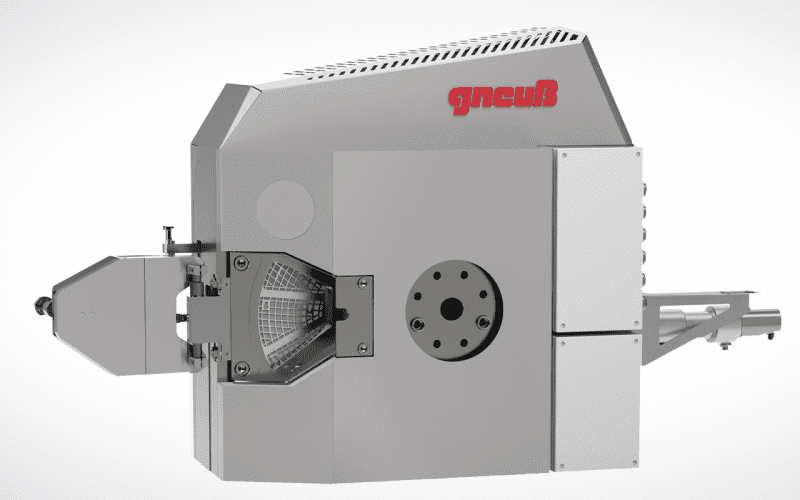

Profile Manufacturing with Gneuss Rotary Filtration Systems

Typical applications are e.g.:

Building profiles/sidings, furniture profiles, ornament moldings, sealing profiles

- Typical materials: rigid and flexible PVC, ABS, PP, PC, elastomers

- Common throughputs up to 1.000 kg/h

- Filtration finenesses down to 50 µm

In profile manufacture, in addition to the removal of solid inhomogeneities, filtration must ensure permanent process and product consistency. Also, material costs can be reduced by using recycled material. For this, Gneuss Filtration Systems offer tailor-made solutions and make cost reductions and top qualities possible.

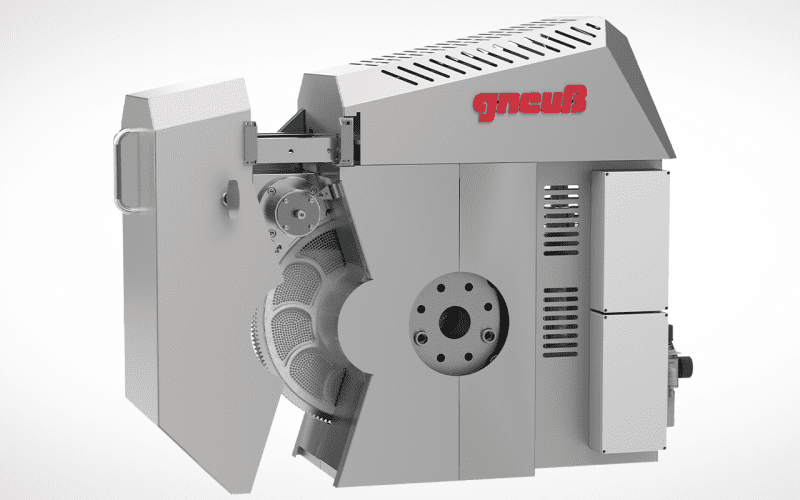

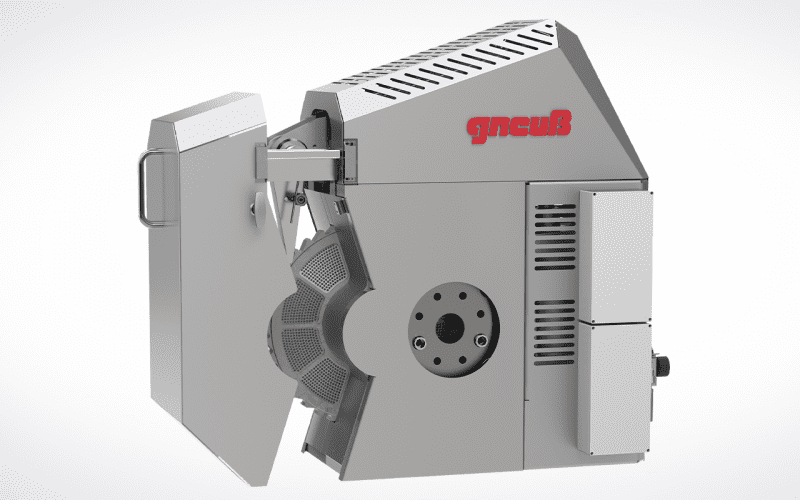

The advantages of Rotary Filtration

- High added value with the use of recycled material

Thanks to the process- and pressure-constant filtration, finer filtration of the melt is made possible. This permanently guarantees high quality and a high line availability, also when recycled material is used. - Good surface finish and good optical properties

The process-constant filtration avoids quality and tolerance variations. Through the static mixture and very fine homogenization of the melt, quality, tensile strength and surface finish of the end product are clearly improved. - Short dwell time of the melt in the filtration system

Due to the optimum rheological design of Gneuss Filtration Systems, the dwell time of the melt in the system is minimized and thus thermal stress is avoided. - No production interruptions, no machine downtime

Changing screens of Gneuss Rotary Filtration Systems does not have any influence on the production process. Thus, it is always guaranteed that the product tolerances are met.