Typical applications are e.g.:

Yarns, nonwovens

- Typical materials: PET, PP

- Common throughputs up to 8.000 kg/h

- Filtration finenesses down to 30 µm

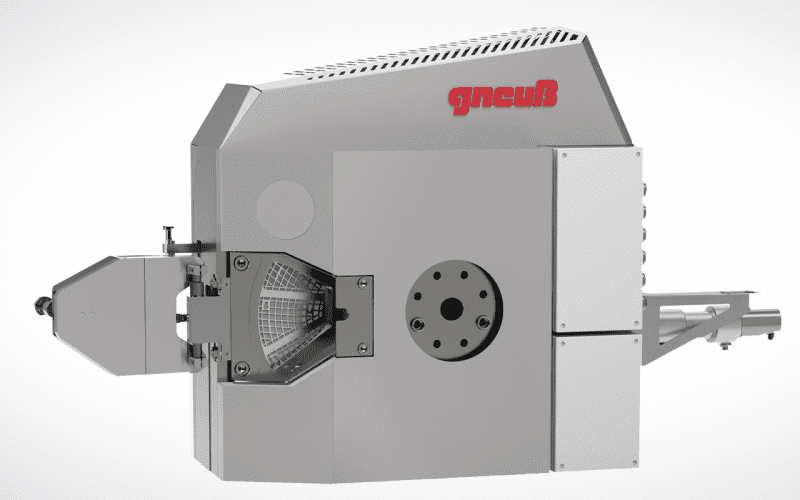

Ultra-fine filtration of the polymer melt before it enters the spinning beam removes solid inhomogeneities and protects both the spinpack and the spinneret. Moreover, in staple fiber manufacture, process consistency regarding pressure and temperature is a basic prerequisite for an efficient production. High throughput rates make a fully-automatic filtration system without any influence on the process necessary. The RSFgenius was developed especially for these requirements and makes continuous cost reductions in the manufacturing process, with top product qualities, possible.

The advantages of Rotary Filtration

- Simple and safe screen changes

Danger to the personnel and environment during filter changes is eliminated. Thanks to the encapsulated design of the RSFgenius and the SFXmagnus any influence from air during the filtration process is avoided. - Consistent material properties thanks to a short dwell time of the melt

Thermal degradation of the melt is avoided, the viscosity remains constant. In this aspect, the RSFgenius and the SFXmagnus are substantially different from conventional candle or disk filters. - Longer spinpack lifetime

The process-constant mode of operation of the RSFgenius as well as of the SFXmagnus avoids any influence on the spinning process all year. Pre-filtration with 40 µm or finer directly upstream of the spinpack is possible, so that the spinpack can be used primarily for melt homogenization. - Reduction of capillary cloggings and filament breaks

A higher melt purity improves the spinpack specifications and therefore leads to a more homogeneous melt as well as to a constant melt flow. - Reduced material costs

The RSFgenius with its integrated self-cleaning makes the use of a greater amount of reclaim (up to 100%) possible, without impairing the product quality. This leads to reduced material costs. - Maximum line availability

Filter or screen changes without any production interruptions and disturbances as well as the fully-automatic mode of operation of the RSFgenius and the SFXmagnus make a maximum line availability possible.