Blown Film

Typical applications are e.g.:

Shopping bags, garbage bags, plastic wrap, hygienic film, shrink wrap film

- Typical materials: LDPE, PVC, LLDPE, HDPE

- Common throughputs up to 250 kg/h

- Filtration finenesses down to 50 µm

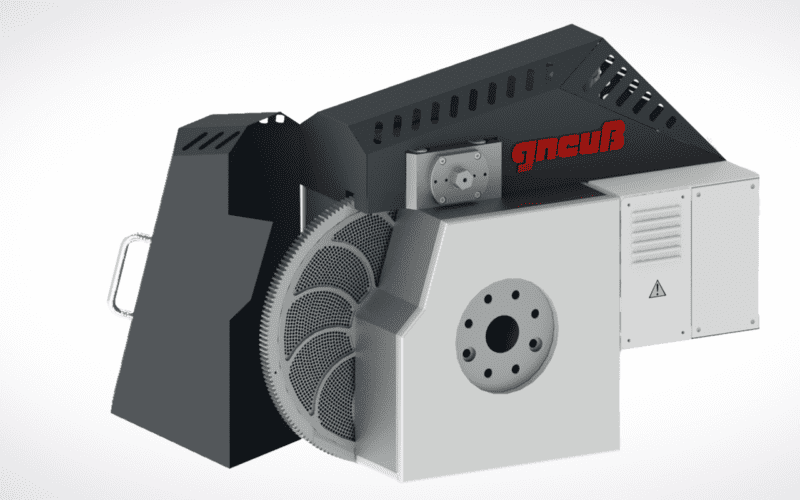

In blown film manufacturing, besides the reliable removal of solid and soft particles in the melt, process-constant production even during screen changes or during the use of reclaim is particularly important. Moreover, the filtration system must exclude the possibility of leakage. For this, Gneuss Filtration Systems offer tailor-made solutions and make continuous cost reduction in the production process, combined with top product qualities, possible.

The advantages of Rotary Filtration

- No fish eyes in the material

Process consistency and the resulting possibility of running finer filtration increase both melt and product quality. - Reduced material costs due to greater use of reclaim

Gneuss Filtration Systems make it possible to process a greater amount of reclaim, without impairing the product quality. This leads to reduced material costs. - Minimum thickness tolerances

The process consistency of the Gneuss Rotary Filtration Technology reduces product tolerances and therefore leads to material cost savings and very good film flatness. - Maximum throughput rate

Fully-automatic screen changes without disturbances and interruptions of the production process make a maximum line availability possible. The RSFgenius and the SFXmagnus even offer the possibility of a fully-automatic operation. - Quality assurance

The gneussconstant mode of operation guarantees better quality of the end product, because the production conditions remain constant and pressure spikes as well as degraded material during screen changes are eliminated.