MP3, an Italian company belongs to I.L.P.A.- Holding. Their specialized factory in Valsamoggia manufactures high quality ABS, ABS/PMMA and PS sheet both for the furnitures and building industry and also for thermoformed technical parts for vehicles, thermo-sanitary sector etc.. In addition to the closed loop recycling of all internal PET scrap, MP3 now focuses on increasing the amount of recycled internal scrap from other thermoplastics such as ABS or PS in their final products.

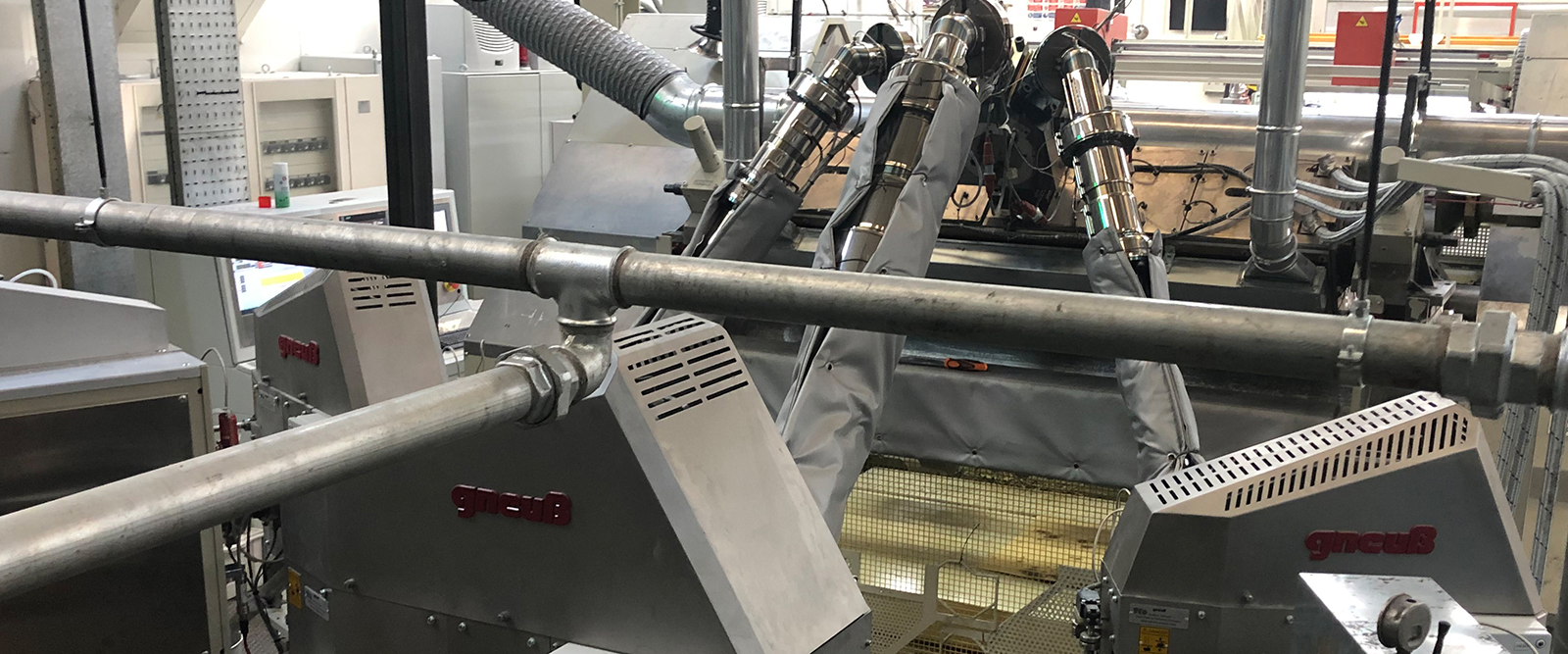

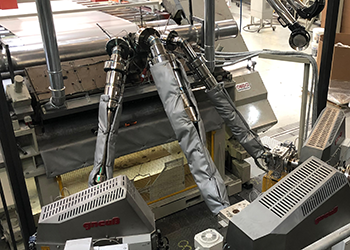

Five years ago, MP3 already replaced three of their existing screen changers with Gneuss SFXmagnus units on one of their sheet lines as previously they had been unable to use high percentages of recycled material without compromising the product quality. This sheet line consists of one main extruder and two co-extruders. PS, ABS and PMMA are processed on this line, with up to three colour changes daily. Thanks to the replacement of the screen changers with Gneuss systems, they were able to add up to 50 % regrind without either process disturbances or quality issues, even with a high contamination load.

The SFXmagnus Screen Changer is characterised by its extremely large active filtration area for its overall external dimensions which means that it is especially well suited for retrofitting to existing lines. As with all Gneuss Rotary Filtration Systems, the screenpacks can be changed during normal production, without pressure spikes or other disturbances. Excellent, consistent sheet surface quality can be ensured and this represents a competitive advantage for MP3.

In 2020, MP3 retrofitted another line with three SFXmagnus Rotary Filtration Systems and a further line was retrofitted with another three units early in 2022.