Waste reduction, avoidance of plastic materials and last but not least recycling are becoming increasingly important. Due to legal requirements and public pressure, manufacturers are faced with growing challenges. On the one hand, the design of plastic packaging must be changed to ensure that the product is recyclable. On the other hand, the proportion of post-consumer recycled material in the product must be increased, ideally up to 100 %.

Production processes that were previously designed only for the processing of virgin material and thus achieved consistently high quality under known conditions, are now severely disturbed or interrupted at higher recycling rates by contamination and strongly fluctuating material qualities. High quality requirements can often no longer be realised with the existing production lines.

In addition, the demand for the increased use of recycled materials in plastic products requires sufficient and regular availability of these. As a consequence, the focus is increasingly shifting to raw material sources that were previously not in focus.

Gneuss extrusion technologies and system solutions for highest standards in packaging recycling

Retrofitting existing lines with Gneuss extrusion technologies

For the processing of recycled materials, an investment in new production facilities is not absolutely necessary – Gneuss is an expert in the recycling of plastics and offers innovative technologies and system solutions for retrofitting. With the replacement of individual key components within the extrusion line, decisive key elements are supplied which make the existing line fit for the recycling cycle. The focus here is on cleaning the plastic melts:

- Gneuss Rotary Melt Filtration Systems for an efficient and economic filtration of plastic melts

- Gneuss MRS Extruders for highly-efficient degassing and decontamination of plastic melts for direct food contact

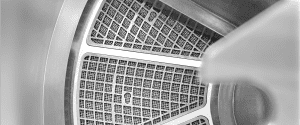

Filtration of highly-contaminated recycled materials with the fully-automatic, pressure-constant and process-constant Gneuss Rotary Filtration Systems

The Gneuss Rotary Filtration Systems with patented filter disc technology are ideally suited for the processing of recycled material, as they operate continuously, with constant pressure and fully automatically. Due to the annular screen arrangement a screen change takes place without disturbances or interruptions of the production process:

- Depending on the filter fineness, the screens can be reused up to 400 times, which can mean a fully automatic filtration process without the need for several weeks of personnel.

- Constant production process even with finer filtration to achieve high end product quality.

- Automatic screen cleaning of the RSFgenius Filtration System by means of an integrated backflush piston system, where a small amount of filtered melt is regularly shot through the dirty screen.

By using the right filtration system, such as the pressure-constant and process-constant RSFgenius Filtration System with back-flushing technology, the quality and productivity restrictions to be expected from a high use of recycled material can be considerably minimized.

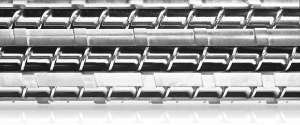

MRS Extruder with high decontamination performance for the direct use of PCR in the production of plastic packaging

When post consumer and industrial waste is processed, the recycled plastics from previous use contain chemical additives such as dyes, stabilizers, acetaldehyde scavengers, carrier oils, solvents and many more. For the use of recycled material in contact with food or skin, the purity requirements set by food authorities such as FDA, EFSA or other local authorities apply. All organic and inorganic potential toxins must be removed, which is achieved with a high decontamination performance during the degassing phase.

For more than a decade, the Gneuss MRS Extruder has been used for the recycling of highly contaminated recycled materials such as post-consumer waste, polyester industrial waste from fibre and film production as well as polystyrene, nylon and other hydrophilic polymers.

The MRS Extruder is based on a conventional single-screw extruder combined with a multiple screw section in the degassing zone:

- the melt surface area available for degassing is increased many times over thanks to the multi-screw element with eight individual satellite screws rotating against the extruder barrel

- vacuum degassing with a simple vacuum of 25-30 mbar

- extremely effective removal of volatile impurities, oils and odours

- processing of polymers with a moisture content of up to 1%

- effective decontamination of 100% post-consumer recycled products and 100% bottle flakes for use in food contact with, among others, the LNO of a North American food safety authority, the EFSA approval or several local approvals

The MRS recycling technology is modular and can be easily integrated into existing production lines. By replacing individual components or integrating the complete Gneuss processing unit, based on a Rotary Filtration System, an MRS Extruder with vacuum system and control technology, existing production processes can be made fit for the recycling cycle.

System solutions for recycling of packaging waste

Gneuss offers turn-key lines for the production of thermoforming sheet from recycled material as well as for the pelletizing of all types of plastic waste.

One area in which MRS extrusion technology is particularly successful is PET sheet extrusion. More than 30 tailor-made Gneuss sheet lines were installed worldwide in recent years. The enormous flexibility of the lines, which process both virgin and recycled material and which are also used for packaging articles with food contact, has convinced many processors:

- economically process without pre-drying and crystallization

- flexible processing of a wide variety of materials such as virgin material, post-consumer bottle flakes and mixtures such as PET and PE or PET and PETG

- many years of experience in processing into a wide variety of packaging products such as transparent film packaging for food and non-food articles, blister packaging, thermoformed trays and trays for food

- flexible conversion to foam film production by means of physical foaming with a density reduction of over 50%.