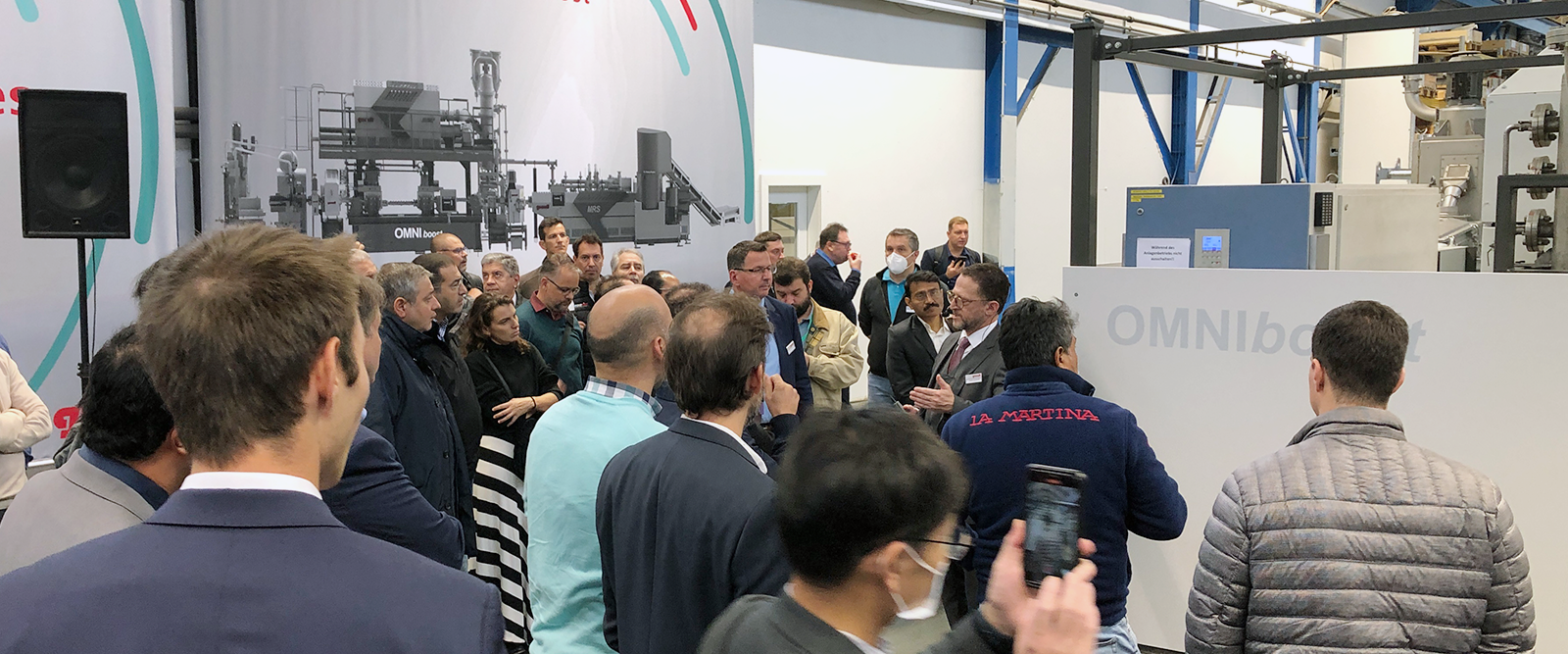

Gneuss Open House in Bad Oeynhausen

During the „K“ Show, Gneuss used the opportunity to demonstrate their OMNI Recycling System in their Technical Center in Westphalia, Germany. On two days, more than 150 guests from all over the world witnessed demonstrations of the new Gneuss OMNIboost Recycling System for processing PET industrial fiber waste (POY). This fiber waste had a residual moisture level of 6 % and an intrinsic viscosity of 0,64 dl/g. This material was fed into the OMNIboost system with at throughput rate of 150 kg/h and thanks to the Gneuss liquid melt phase IV booster, the viscosity was increased. The visitors were impressed by the speed of the IV boost: with a residence time within minutes, the IV was increased to 0,66. For an IV boost to 0,84 a residence time less then half an hour was required.

The OMNIboost Recycling System is designed for recycling both post-industrial and post-consumer PET waste with a low bulk density, such as waste fibers, or thin film. Without the need for any thermal pre-treatment, the material is fed into the Gneuss 3C Rotary Feeder, which cuts and compacts the material as well as feeding it directly into the MRS Extruder screw.

The Gneuss MRS extruder is based on the simple and rugged single screw extruder, however it is equipped with a multiple screw section for optimised degassing. The patented multiple screw design from Gneuss has a section of extruder screw (Multi Rotation Section MRS) with a number of satellite screws, which rotate in the opposite direction to the main screw, creating a huge surface area and ensuring an extremely rapid surface area exchange rate. This ensures unparalleled degassing performance in the melt phase, with minimal stress on the material and can decontaminate post-consumer PET to food contact requirements without the need for thermal pre-treatment of the material prior to extrusion.

After passing through the extruder, the polymer melt is filtered with the highly efficient Gneuss RSFgenius Melt Filtration System. This system ensures that even with high contamination loads, fine filtration is possible without pressure or flow disturbances and with minimised polymer loss.

Still in the melt phase, the polymer flows into the Gneuss JUMP liquid phase IV booster reactor. The viscosity of the melt is measured both on the inlet and outlet of the reactor. The viscosity is boosted to the required level by regulating the vacuum level, residence time and surface area exchange rate in the reactor vessel. With an assured, constant output viscosity the material can be fed to the production process (for example: fiber spinning, strapping tape) whilst still in the melt phase. By ensuring that the polymer remains in the melt phase from the extruder to the final processing stage, the OMNIboost recycling process represents the fastest and most efficient way to reprocess PET where a viscosity boost is required.