GNEUSS EXTRUSION TECHNOLOGY

New OMNI Recycling Machines for closed loop recycling of PET, PS and polyolefin post-consumer reclaim

Gneuss’ MRS Extrusion Technology has proven itself as an alternative for the reprocessing of contaminated materials like polyester, polystyrene, polypropylene or polyethylenes. In combination with the highly efficient Gneuss Rotary Filtration Systems and optimized vacuum technology, customizable recycling lines tailor-made for a specific material can be engineered. Several Letters of Non Objection (LNOs) from the North American food safety authority, EFSA conformity and local approvals in Latin America confirm the decontamination efficiency of the technology. Samples of polypropylene tubs for food applications made with 30 % post consumer PP and PS sheet made from 30 % post consumer PS, processed on Gneuss OMNI Recycling Machines with MRS extruders and RSFgenius filtration systems, will be shown at K.

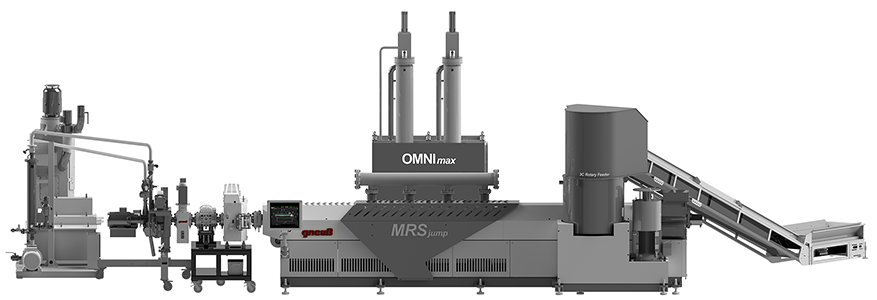

OMNI Recycling Machine for post-consumer fiber or thermoform reclaim

Gneuss will show its latest machinery innovations for today’s and tomorrow’s recycling needs with a complete OMNI Recycling Machine featuring a new 3C Rotary Feeder, an MRSjump 70 extruder, a fully automatic melt filtration system RSFgenius 90 and an online viscometer VIS, for the processing of 200 kg/h (450 lbs/h) of undried and uncrystallized polyester (PET) thermoform reclaim.

3C Rotary Feeder

The newly developed 3C Rotary Feeder makes it possible to use low bulk density materials without any external processing steps. A conveyor belt feeds shredded reclaim material into the hopper, where a fast-rotating disc with knives cuts, compacts and pre-conditions the material. The knives add energy into the material and start the heating and degassing process before the material is automatically fed into the MRSjump extruder.

MRSjump

The MRS extruder is based on conventional single screw extruder but is equipped with a multiple screw section for devolatilization. It enables very efficient and gentle decontamination of PET, whilst achieving the requirements for direct food contact standards. The MRS extruder permits the processing of R-PET directly into high quality end products such as packaging sheet, strapping tape or filaments without pre-drying by using a simple and rugged vacuum system. This is achieved by means of its unique and patented processing section. The Multi Rotation Section is a drum containing multiple satellite single screws, driven by a ring gear and pinion transmission.

The satellite screws rotate in the opposite direction to the main screw. This disproportionately increases the surface exchange of the polymer melt. A large opening for venting, exposing the full length of the satellite screws, is completely under vacuum. This provides excellent and unrestricted access to the polymer melt, the surface of which is constantly replaced at an extremely high rate by the action of the satellite screws in the multiple screw section. The surface area – and the surface area exchange rate – available for devolatilization are far greater than in other extrusion systems. As the thermal and mechanical stress on the polymer melt is minimized, PET processed on the MRS extruder has excellent optical and mechanical properties.

The new MRSjump has a longer, modified version of the Multi Rotation Section, which ensures both a longer residence time of the material and more surface area exchange under vacuum. The longer Multi Rotation Section, coupled with a powerful vacuum system operating at 1 mbar, can be used to boost the viscosity of R-PET and to hold it at a stable level in spite of variations in the input material. Therefore, there is no need for any liquid phase (LSP) or solid state polymerization (SSP). With the stabilization and/or increase of the intrinsic viscosity in the extrusion process, the MRSjump is especially well suited to recycling e.g. PET film waste or fiber reclaim – applications for which direct recycling with one single extrusion step was previously impossible due to low intrinsic viscosity or variable input viscosities. In combination with Gneuss’ Rotary Filtration Technology, a high melt purity is guaranteed. Quality assurance can be provided with an online viscometer VIS for measuring melt viscosity.

As demand for PET bottle flakes outpaces supply and processors are looking for alternative feedstock (e.g. to fullfill recycled content mandates) the MRSjump offers an excellent solution for PET thermoform, film or fiber recycling, while the newly developed MRS cutter compactor makes it possible to use low bulk density materials.

In parallel, with Gneuss’ headquarters only about 200 km from the show, a complete PET sheet extrusion line with an OMNImax Recycling Machine – consisting of an MRSjump 70, Gneuss’ deep vacuum system and a fully-automatic filtration system RSFgenius 75 – and a sheet downstream with a 500 mm wide extrusion die will be running in Gneuss’ technical center open to visitors.

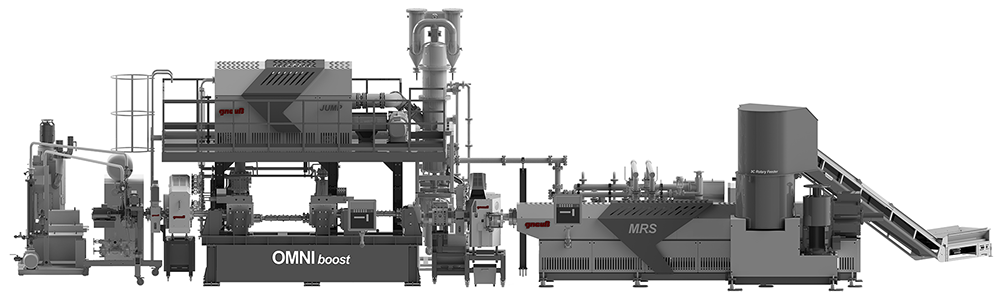

OMNIboost Recycling Machine including polyreactor JUMP

Additionally, an OMNIboost Recycling Machine with a polyreactor JUMP will be operating in Gneuss’ technical center for an online demonstration. The JUMP can lift the IV value of a PET melt up to 0.95 dl/g.

In the JUMP the polymer passes over several slow turning elements which create a polymer film, the surface of which is constantly renewed. The reactor vessel is kept under vacuum, through which volatile substances are reliably removed. By regulating the residence time in the reactor, the vacuum, the fill level and the speed of rotation of the agitating devices, the polycondensation reaction can be altered to achieve the required product properties. The JUMP is a robust and reliable liquid state polycondensation system (LSP) and a compact, quick and efficient alternative to conventional solid state systems (SSP). It enables direct reintroduction of the polymer into the production process without the need to remelt the PET.

GNEUSS FILTRATION TECHNOLOGY

Various models on display

Gneuss Filtration Technology will exhibit several different models of their patented Rotary Filtration Systems. These continuous filtration systems are characterized by a filter disk on which the screen cavities are located in a ring pattern. Screens can be changed on the part of the filter disk that is not active in the melt channel, while the production process continues to run without any interruptions or disturbances.

Gneuss’ top model, the RSFgenius, operates with an integrated back-flushing system offering self-cleaning for very demanding applications and highest quality requirements. Screens can be automatically re-used up to 400 times, and filtration finenesses below 10 microns/1200 mesh are available. There will be an RSFgenius 250 on display, with an active screen area of 1350 cm2/209 square inches, for throughputs of several thousand kilos per hour, depending on the type of polymer and the filtration fineness.

Retrofitting a fully-automatic RSFgenius to an existing extrusion line, whether in a pelletizing, sheet, fiber or pipe application, permits the use of more contaminated (and often cheaper) material and/or the use of finer screens. Every retrofit is tailor-made and usually without the need to move any existing equipment.

There will also be an SFneos 150 and an SFXmagnus 90 on display. These models are also continuous, pressure and process constant, but not backflushing, therefore these systems are for applications that don’t require self-cleaning. The SFneos 150 offers an active filtration area of 450 square centimeters/ 70 square inches for applications like foam sheet, battery separator or PVC. The SFXmagnus 90, with its completely encapsulated design, offers an active filtration area of 350 square centimeters/ 54 square inches for applications like PET or BOPP sheet or other sensitive materials.

GNEUSS MEASUREMENT TECHNOLOGY

Measuring Technology for Extrusion – Flexible, Fast, Safe, Digital

Gneuss provides flexible sensor solutions for pressure and temperature measurements, individually tailored to your application. Abrasion, corrosion, temperature, Gneuss offers the right solution for every challenge.

Gneuss delivers fast. Whether standard sensor or application-specific customized solution. The flexible manufacturing structure allows shortest delivery times.

Gneuss creates safety. In addition to standard-compliant pressure monitoring, Gneuss offers the necessary quality assurance of the measuring equipment.

Gneuss is digital. The latest generation of Gneuss sensors and pressure monitors communicates completely digitally. Integrated RFID chips for digital gauge monitoring are available for all sensor models.